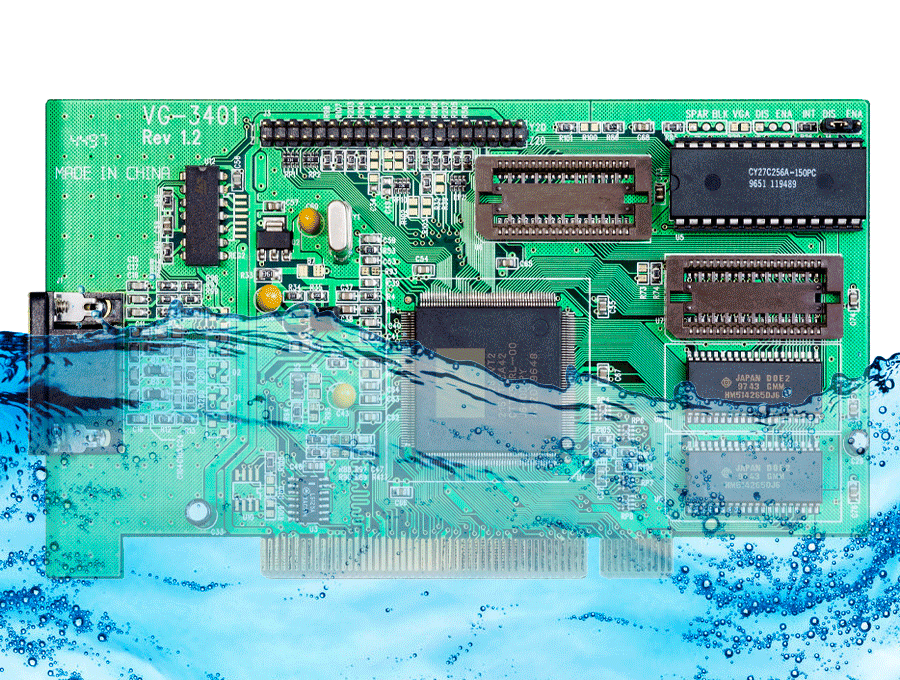

Cleaning of PCBAs and (mounted) misprints

As a manufacturer and system supplier kolb provides for the cleaning of assembled PCBs and mounted misprints the complete process from a single source: including machinery, accessories, cleaners and specially applied software controlled fully automated electronic processes.

The cleaning of assemblies (PCB cleaning) is almost mandatory today, particularly in high-end area. These boards (assembled / mounted PCBs) must be cleaned thoroughly of production residues and possible environmental and handling dirt to ensure a reliable further processing respectively a trouble-free performance.

Especially where sensitive and thus mostly expensive modules are used, such as in the aerospace industry, the automotive industry, in medical technology or telecommunications, the assembled PCB cleaning is a full and important production step.

But even with the so-called no-clean manufacturing, it may be that these components must be cleaned to avoid malfunctions.

The thorough removal of flux residues, colophony, resin, oxides and soldering materials are the main tasks in the cleaning of printed circuit boards, active and passive electronic components, BGA, flip chip, relays, inductors, etc.

In addition to cleaning PCBAs, this process can also be used to clean already single side mounted misprints.

The cleaning of an assembly is not only a necessary prerequisite for reliable bonding and / or varnishing and so e.g. for climate security / avoiding current leakages. Assembled PCBs cleaning also allows debugging and so preserves the value of misprints and / or ensures the optical quality of the electronic components.

Suitable cleaning systems

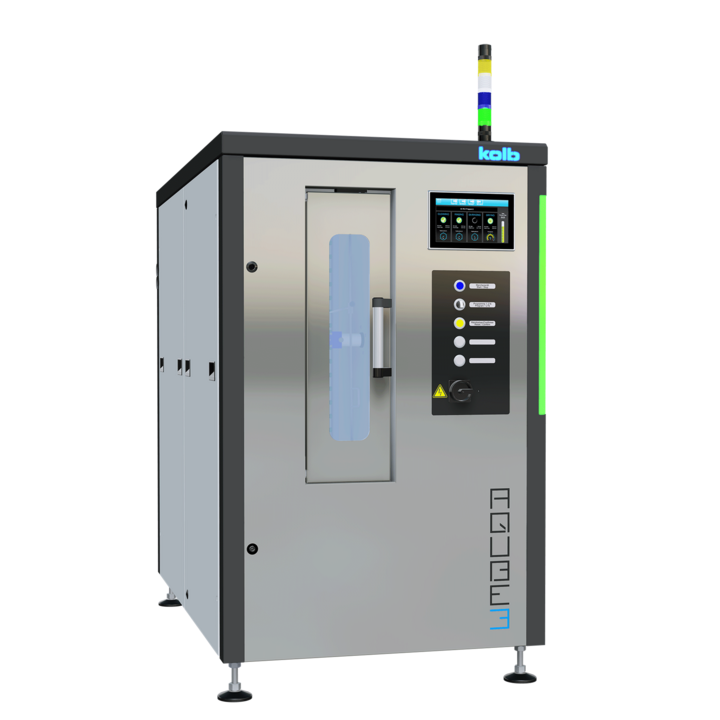

AQUBE® XH9

Fully automatic high end batch cleaner with largest process chamber worldwide

Capacity: up to 830 standard eurocards equals 19 m² (204.5 ft²) in up to four variable drawer baskets Horizontal up to eightfold spray rotors, VMH®-TurboDigital evaporative drying

Process chamber dimensions: W 970 • D 955 • H 900 mm (W 38.18" • D 37.59" • H 35.43")

more about AQUBE® XH9

AQUBE® XH7

Fully automatic high end XL batch cleaner for assembled PCBs

Capacity: up to 540 (8.6 m² / 92.5 ft²) standard eurocards in up to three variable drawer basketsPolyPower® Technology (up to three times more pressure power and up to 30% less cycle time)

Horizontal up to sixfold spray rotors, VMH® TurboDigital evaporative drying

Process chamber dimensions: W 700 • D 720 • H 710 mm (W 27.55" • D 28.34" • H 27.95")

more about AQUBE® XH7

AQUBE® XH5

Fully automatic high end assembled PCBs batch cleaner

Capacity: up to 176 (2.8 m²/30 ft²) standard eurocards in up to two variable drawer basketsPolyPower® Technology (up to three times more pressure power and up to 30% less cycle time)

Horizontal up to fourfold spray rotors, VMH® TurboDigital evaporative drying

Process chamber dimensions: W 540 • D 590 • H 570 mm (W 21.25" • D 23.22" • H 22.44")

more about AQUBE® XH5

AQUBE® MV3 ONE

Fully automatic compact highend cleaning system for stencils and many more

Capacity: Screen, stencil, carrier, washing frame (PCBAs, Misprints, Squeegees) up to 770 x 950 mm (31" x 37")Fully automatic 4step process, cleaning, MediumWipe®, rinsing and CWA® supercharger drying

Cleans stencils, screens, PumpPrint stencils, misprints from SMD adhesive, SMD paste, flux, oil, dust, grease

more about AQUBE® MV3 ONE

AQUBE® LH7

Fully automatic state of the art PCB XL batch cleaner

Capacity: up to 540 (8.6 m² / 92.5 ft²) standard eurocards in up to three variable drawer basketsHorizontal up to sixfold spray rotors, VMH®-TurboDigital evaporative drying

PolyPower® Technology (up to three times more pressure power and up to 30% less cycle time)

Process chamber dimensions: W 700 • D 720 • H 710 mm (W 27.55" • D 28.34" • H 27.95")

more about AQUBE® LH7

AQUBE® LH5

Fully automatic standard assembled PCBs batch cleaner

Capacity: up to 176 (2.8 m² / 30 ft²) standard eurocards in up to two variable drawer basketsHorizontal up to fourfold spray rotors, VMH®-TurboDigital evaporative drying

PolyPower® Technology (up to three times more pressure power and up to 30% less cycle time)

Process chamber dimensions: W 540 • D 590 • H 570 mm (W 21.25" • D 23.22" • H 22.44")

more about AQUBE® LH5

PSE 300 2VL

Fully automatic two-tank two-circuit stencil cleaning system

Capacity: Screen, stencil, carrier, washing frame up to 770 x 950 mm (30" x 37")Fully automatic 4step process, cleaning, MediumWipe®, rinsing and CWA® supercharger drying

Cleans stencils, screens, PumpPrint stencils, misprints from SMD adhesive, SMD paste, flux, oil, dust, grease

more about PSE 300 2VL

PSE LH5

Fully automatic economy assembled PCBs batch cleaner

Capacity: up to 176 (2.8 m² / (30 ft²) eurocards in up to two variable drawer basketsHorizontal up to fourfold spray rotors, VMH®-Turbo evaporative drying

Process chamber dimensions: W 540 • D 590 • H 570 mm

more about PSE LH5

PSE LH7

Fully automatic XL economy PCB cleaner

Capacity: up to 540 (8.6 m² / 92.5 ft²) eurocards in up to three variable drawer basketsHorizontal up to sixfold spray rotors, VMH®-Turbo evaporative drying

Process chamber dimensions: W 700 • D 720 • H 710 mm (W 27.55" • D 28.34" • H 27.95")

more about PSE LH7

Suitable detergents

FR60 / FR100

Manual flux remover sprays

Cleaning sprays for quick and/or intensive manual PCBA cleaning of normal and stubborn flux residues.

FR60 / FR100

MultiEx® 3D-A3

Special cleaner for power electronics / DCBs

Removes copper oxides / CuO, aluminium oxides, SMD paste, fluxes, solder pastes (soldered) from DCBs, PCBAs, ceramic substrates, aluminium, non-ferrous metals.

MultiEx® 3D-A3

MultiEx® 3D-H2

broadband cleaner for PCBAs especially with large metal surfaces

Removes SMD paste, rosin flux, fluxes, copper oxides / CuO, aluminium oxides from PCBAs, DCBs, ceramic substrates, aluminium, non-ferrous metals.

MultiEx® 3D-H2

MultiEx® A12

Broadband detergent most suitable for solder carriers, solder pallets, ESD boxes, PCB storage magazines and PCBAs

Aqueous alkaline detergent for use in kolb systems with PowerSpray® and AirFlow® technology as well as in any common spray-in-air and spray-in-immersion cleaning system. Most suitable for solder carriers, solder pallets, ESD boxes, PCB storage magazines and PCBAs

MultiEx® A12

MultiEx® NP-1

Multifunctional pH-neutral detergent especially for PCBAs and power electronics

Aqueous, pH-neutral broadband cleaner especially for PCBAs and power electronics for the removal of flux and solder pastes.

MultiEx® NP-1

MultiEx® Rapid

Intensive lux remover

Detergent concentrate that removes particularly flux residues quickly, thoroughly and with best possible product care from assembled PCBs.

MultiEx® Rapid

MultiEx® VR-18

Single phase special cleaner for hard to clean fluxes on PCBAs

Removes especially hard to clean fluxes from PCBAs ceramic substrates, misprints, stencils, solder carriers and pallets, ESD boxes, PCB magazines.

MultiEx® VR-18

MultiEx® VR-HPA

Highend broadband cleaner for PCBAs with sensitive components

Removes fluxes and pastes especially from PCBAs with sensitive components, from ceramic substrates, misprints, stencils, solder carriers, solder pallets, ESD boxes, PCB magazines.

MultiEx® VR-HPA

MultiEx® VR-SP

High end broadband detergent for PCBAs and many more

Removes all commercially available fluxes and pastes from assembled PCBs, ceramic substrates, misprints, stencils, solder carriers, solder pallets, ESD boxes, PCB magazines.

MultiEx® VR-SP