Cleaning of stencils, screens and unmounted misprints

As a manufacturer and system supplier kolb provides for stencil, screen and misprinted bare boards cleaning the complete process from a single source: including machinery, accessories, detergents and specially applied software controlled, fully automated electronic processes.

Optimum screen cleaning (or cleaning of screen stencils, or stencil plates, as well as VectorGuard stencils) is a prerequisite for reproducible quality and low failure rates in both electronics and solar cell production today. Residues and contamination from SMD adhesives and SMD solder pastes on screens and stencils, especially in the apertures, lead to printing errors during PCBA production and thus malfunctions of the finished product.

In addition to cleaning stencils from adhesive and paste, this process can also be used to clean misprints (misprinted bare boards) as well as solder frames / solder masks and carriers of solder paste, conductive pastes, adhesive, flux, oil, grease or dust.

A couple of decisive questions have to be answered when designing a process consisting of machine, detergent and reproducible process control:

- Can the process effectively and material conserving clean fine and ultra fine-pitch apertures?

- What exact contaminations need to be cleaned now and in a foreseeable future?

- Can the process clean dry/older and fresh contaminations?

- Is the whole process environmentally safe and compliant?

- What is the total cost of ownership (investment, operating cost, maintenace time/downtime)?

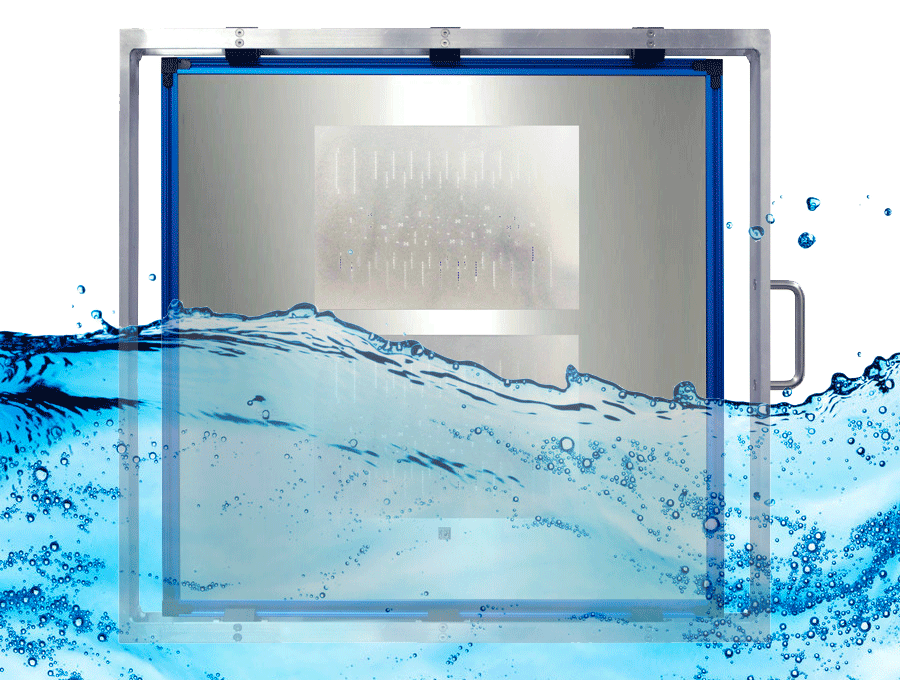

Suitable cleaning systems

PSE 300 HD

Compact fully automatic fine cleaning economy system for stencils/screens

Capacity: Screen, stencil, carrier, washing frame up to 770 x 850 mm (30" x 33")2step process (cleaning/rinsing, drying) with HotSpeed warm air drying

Average process time: 30 min per stencil

more about PSE 300 HD

PSE 300 VL

Compact fully automatic fine cleaning economy system for stencils/screens

Capacity: Screen, stencil, carrier/washing frame up to 780 x 950 mm (31" x 37")3-step process (cleaning/rinsing, MediumWipe®, CWA® drying)

Average process time: 13 min per stencil

more about PSE 300 VL

PSE 300 VS

Fully automatic, single chamber PowerSpray® system with 2-step process

Fully automatic single chamber system with PowerSpray® technologyCleans: screens, stencils, solder carriers and misprints

Usabel chamber dimension: W 350 • D 1,000 • H 920 mm

more about PSE 300 VS

PSE MV3 ONE

Compact fully automatic fine cleaning economy system for stencils/screens

Capacity: Screen, stencil, carrier, washing frame up to 770 x 950 mm (30" x 37")Fully automatic 4step process, cleaning, MediumWipe®, rinsing and CWA® supercharger drying

Cleans stencils, screens, PumpPrint stencils, misprints from SMD adhesive, SMD paste, flux, oil, dust, grease

more about PSE MV3 ONE

PSE MV3 ONE XL

Compact fully automatic fine cleaning economy system for extra large stencils/screens

Capacity: Screen, stencil, carrier, washing frame up to 770 x 1,560 mm (30" x 61")Fully automatic 4step process, cleaning, MediumWipe®, rinsing and CWA® supercharger drying

Cleans stencils, screens, PumpPrint stencils, misprints from SMD adhesive, SMD paste, flux, oil, dust, grease

more about PSE MV3 ONE XL

PSE MV3 ONE XXL

Economy special system for the fine cleaning of super large stencils

Capacity: Stencil/screen up to 1,500 x 1,560 mm (59" x 61")Fully automatic 4step process, cleaning, MediumWipe®, rinsing and CWA® supercharger drying

Cleans screens and stencils from SMD paste, SMD adhesive, soldering support substances, oil & dust

more about PSE MV3 ONE XXL

PSE MV8 TWIN

Economy fine cleaning system for two large stencils/screens in one cycle

Capacity: 2 Stencils, screens, carriers up to 800 x 900 mm (32" x 35")Fully automatic 4-step process, cleaning, MediumWipe®, rinsing and CWA® supercharger drying

Cleans screens, stencils and PumpPrints from SMD paste, SMD adhesive, soldering support substances, oil & dust

more about PSE MV8 TWIN

AQUBE® MV3 ONE

Compact fully automatic high-end fine cleaning system for stencils/screens

Capacity: Screen, stencil, carrier, washing frame (PCBAs, Misprints, Squeegees) up to 770 x 950 mm (31" x 37")Fully automatic 4-step process, cleaning, MediumWipe®, rinsing and CWA® supercharger drying

Cleans stencils, screens, PumpPrint stencils, misprints from SMD adhesive, SMD paste, flux, oil, dust, grease

more about AQUBE® MV3 ONE

AQUBE® MV8 sTWIN

Twofold screen/stencil fine cleaning system with sequential utilization option

Capacity: 2 Stencils, screens, carriers up to 950 x 770 mm (37" x 30") in two separate process chambersFully automatic 4step process: cleaning, MediumWipe®, rinsing and CWA® supercharger drying

Cleans stencils, screens, PumpPrint stencils, misprints from SMD adhesive, SMD paste, flux, oil, dust, grease

more about AQUBE® MV8 sTWIN

AQUBE® MV9 QUAD

Fully automatic large-scale fine cleaning system for four screens/stencils

Capacity: 4 screens/stencils/carriers up to 800 x 940 (31.5“ x 37")Vertical eightfold spray rotors, CWA® supercharger compression drying

Relative cycle time: 7 minutes per stencil

Process chamber dimensions: W 970 • D 955 • H 900 mm (W 38.18" • D 37.59" • H 35.43")

more about AQUBE® MV9 QUAD