Cleaning of DCBs & ceramic substrates (power electronics)

As a manufacturer and system supplier kolb provides for the cleaning of DCBs, ceramic cubstrates and hybrids the complete process from a single source: including machinery, accessories, cleaners and specially applied software controlled fully automated electronic processes.

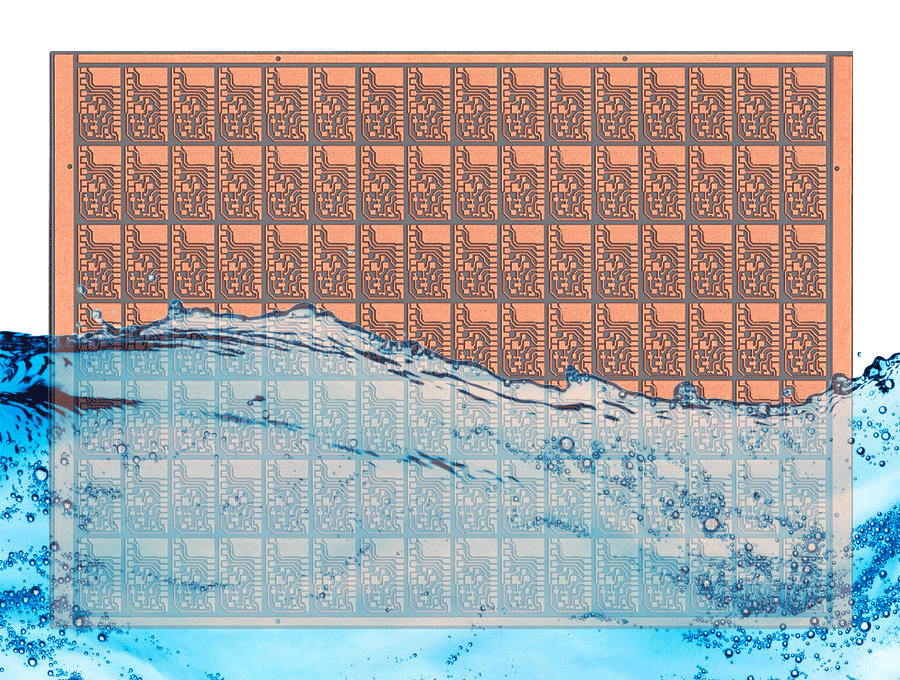

Direct copper bonding (DCB) substrates are often used due to their good thermal conductivity in high-performance modules. They consist of a ceramic substrate board, usually alumina or aluminum nitride and usually applied with a copper foil on one or both sides in a high temperature oxidation process. Precisely because of the high power requirements (DCB substrates carry currents up to several thousand volts at temperatures up to 200° C), these components must be absolutely free of production residues for further working processes such as wire bonding, coating or varnishing.

Thorough removal of flux, rosin, resin, Cu oxide and soldering support substances are the main tasks in the cleaning of DCBs, hybrids, assemblies / assembled printed circuit boards, in order to be able to offer correspondingly process-safe assemblies for the above mentioned subsequent processes.

Suitable cleaning systems

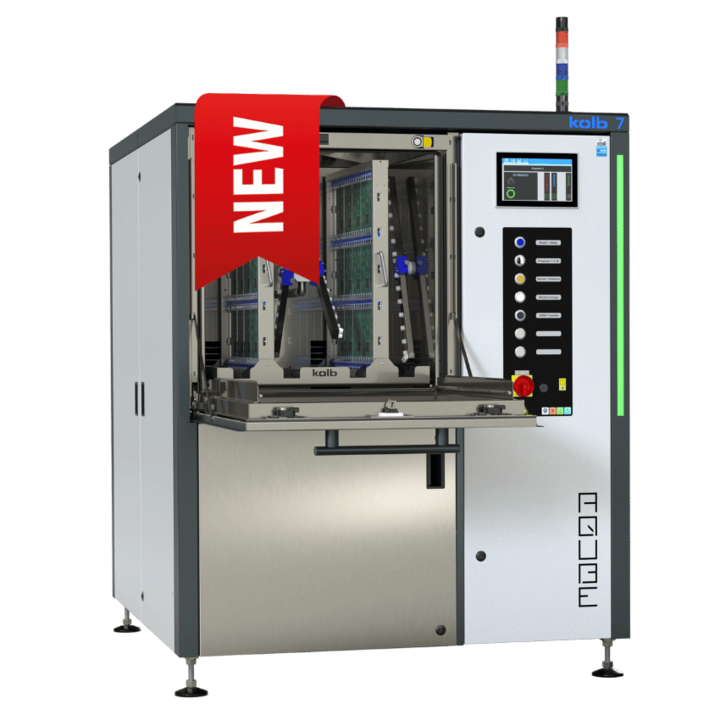

AQUBE® XH7

(also available as AQUBE® XH7 TZD)

Fully automatic high end ultra-fine cleaning system for assemblies/printed circuit boards

Capacity: up to 522 (8.4 m² / 90,4 ft²) eurocards in up to three variable drawer basketsPolyPower® Technology (up to three times more pressure power and up to 30 % less cycle time)

Horizontal up to sixfold spray rotors, VMH® TurboDigital evaporative drying

Process chamber dimensions: W 700 • D 720 • H 710 mm (W 27.55" • D 28.34" • H 27.95")

more about AQUBE® XH7

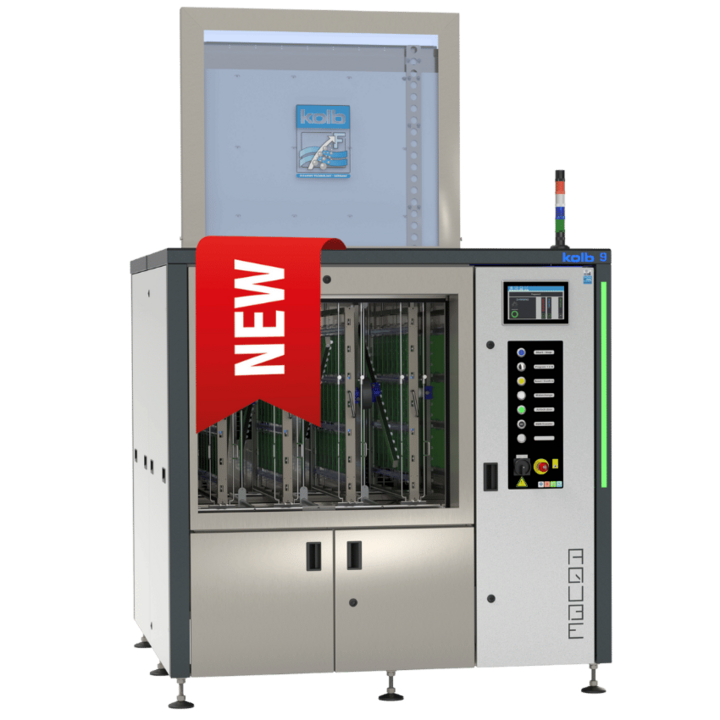

AQUBE® XH9

Fully automatic high-end ultra-fine cleaning system for mass cleaning of PCBAs

Capacity: up to 900 standard eurocards equals 14.4 m² (155 ft²) in up to four variable drawer baskets Horizontal up to eightfold spray rotors, VMH® TurboDigital evaporative drying

Process chamber dimensions: W 970 • D 955 • H 900 mm (W 38.18" • D 37.59" • H 35.43")

more about AQUBE® XH9

AQUBE® XV7 SuperTask

Special system for cleaning assemblies/printed circuit boards with complex architectures

Capacity: 30 eurocards in two clamping frames of 15 cards each in a washing cartCleans PCBAs, hybrids and misprints from flux residues, resin, copper, oxide and soldering support substances

Process chamber dimensions: W 700 ▪ H 710 ▪ D 720 mm (W 27.55"▪ H 27.95" ▪ D 228.34")

more about AQUBE® XV7 SuperTask

AQUBE® XV9 SuperTask

Fully automatic high-end ultra-fine cleaning system for mass cleaning of PCBAs

Capacity: 96 eurocards in four clamping frames of 24 cardsVertical PTFE mounted rotor system with eight spray rotors for thorough wetting (no blind spots)

Process chamber dimensions: W 970 • D 955 • H 900 mm (W 38.18" • D 37.59" • H 35.43")

more about AQUBE® XV9 SuperTask