kolb offers a machine process for fast and thorough paint stripping as a turnkey solution from one manufacturer source consisting of cleaning system, paint stripper and individually programmed process control. As cleaning systems here all kolb AQUBE® and PSE MH PowerSpray® pressure spray-in air systems can be considered. They are operated for varnish and coating cleaning with the homogeneous paint stripper kolb RemoCoat® SG, especially developed for paint stripping tasks in the electronic industry (Product information and Safety data sheet).

The cleaning spectrum covers almost all common types of paint / varnish and carrier materials. The process window allows best results at low cleaning temperatures of well below 60 °C, which have never been reached in paint stripping before.

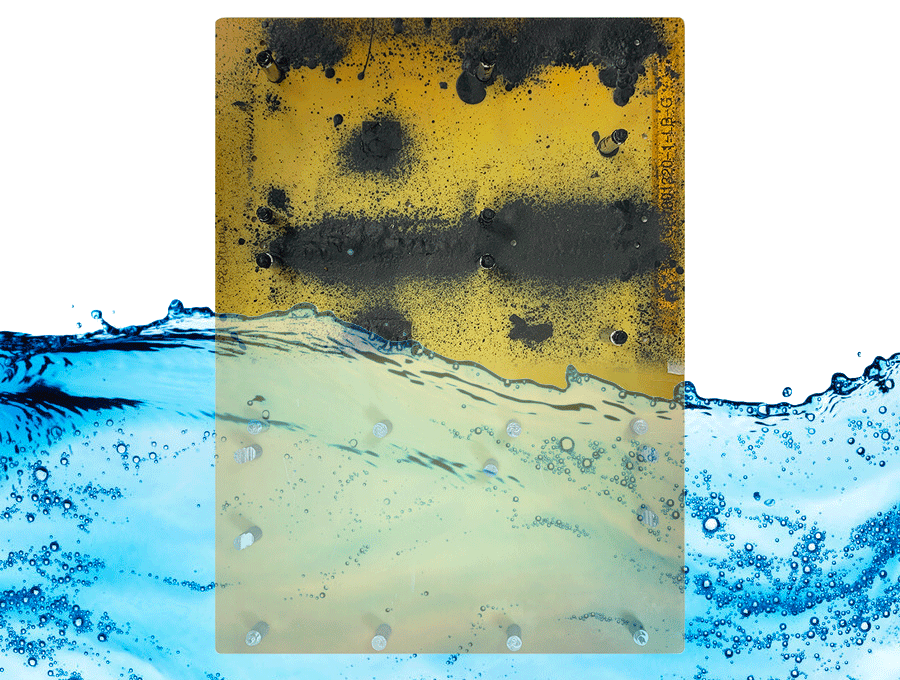

The special cleaning agent RemoCoat® SG attacks the binder layer of the paint, which then disintegrates. The cleaned paint residues can then simply be filtered out of the homogeneous (no phase separation) paint stripper.

Due to the special 4Step process (cleaning, drying, rinsing with tap water, drying) not only is the paint stripped product completely clean, but the residues remain as dry powder that can be easily disposed of from the filter with which all paint cleaning systems are equipped.

Depending on the product characteristics of the varnish and the age of the paint residues as well as the material properties of the good to be cleaned, the electronic process control is adjusted in detail so that the entire process then runs stably and reproducibly automatically at the touch of one button.

A precise process analysis is therefore always advisable in advance to find the best possible combination of machine, detergent, coating used and product to be cleaned.

Economy tools cleaning systems for solder carriers, pallets, trays and in its high temperature version perfectly suited for the cleaning of conformal coating carriers

4Step process (cleaning / drying / rinsing / drying) with VMH® hot air evaporative drying

Capacities

PSE MH7: 11 carriers up to 710 x 580 mm (28“ x 123“) or up to three drawer baskets for small parts

PSE MH5: 7 carriers up to 480 x 430 mm (19“ x 17“), boxes / racks up to 540 x 590 x 570 mm or up to two drawer baskets

Process chamber dimensions

PSE MH7: W 700 • D 720 • H 710 mm (W 27.55" • D 28.34" • H 27.95")

PSE MH5: W 540 • D 590 • H 570 mm (W 21.25" • D 23.22" • H 22.44")

State of the art tools and parts cleaning systems for solder carriers, pallets, trays and in its high temperature version perfectly suited for the cleaning of conformal coating carriers

4Step process (cleaning / drying / rinsing / drying) with VMH® hot air evaporative drying

Capacities

AQUBE® MH9: 14 carriers up to 950 x 750 mm (37.5“ x 29.5“), boxes / racks up to 970 x 955 x 900 mm or up to four drawer baskets for small parts, filters etc

AQUBE® MH7: 11 carriers up to 710 x 580 mm (28“ x 123“) or up to three drawer baskets

AQUBE® MH5: 7 carriers up to 480 x 430 mm (19“ x 17“), boxes / racks up to 540 x 590 x 570 mm or up to two drawer baskets

Process chamber dimensions

AQUBE® MH9: W 970 • D 955 • H 900 mm (W 38.18" • D 37.59" • H 35.43")

AQUBE® MH7: W 700 • D 720 • H 710 mm (W 27.55" • D 28.34" • H 27.95")

AQUBE® MH5: W 540 • D 590 • H 570 mm (W 21.25" • D 23.22" • H 22.44")

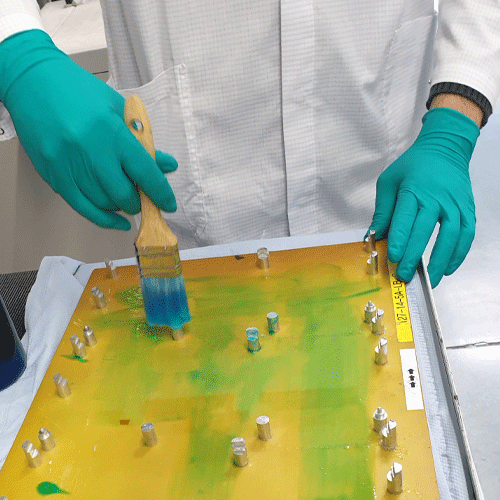

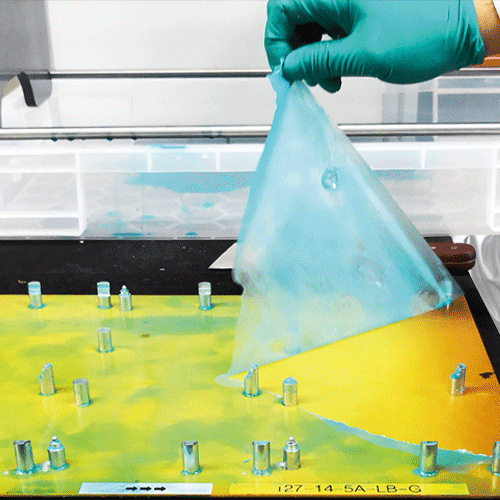

kolb CarrierSeal® is a liquid sealant for painting carriers / product carriers or for the chamber parts of conformal coating systems. Varnish / coating residues, which normally stubbornly adhere directly to the tools or in the chamber, can be removed by simple manual peeling and/or machine cleaning of the sealing film applied before the coating process.

If sealed coating carriers or chamber parts are so heavily contaminated with coating residues that optimal function is no longer guaranteed, these residues can be quickly removed by simply peeling off the CarrierSeal® sealant. This manual removal is particularly advantageous for previously sealed parts of a coating system.

The CarrierSeal® sealant can also be cleaned even more easily by machine in a suitable electronic cleaning system. The carrier contaminated with paint residues is fixed in a washing frame for machine cleaning. This is very efficient and even more time-saving, especially for coating carriers with lots of superstructures.

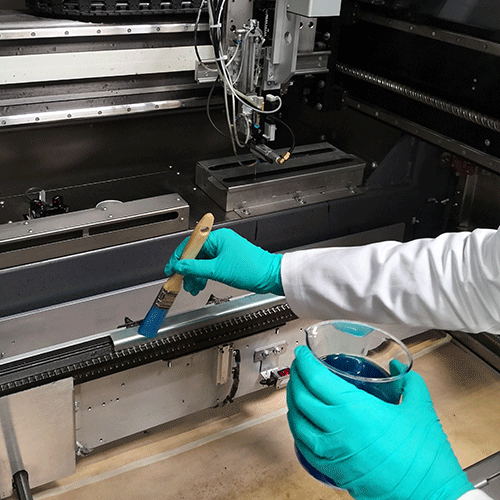

For machine cleaning it is recommended to use a pressure spray system with vertically working rotors, in which normally stencils or PCBAs are cleaned. It is advantageous if the system has a warm or hot air drying function. However, it is also possible to use systems with horizontally arranged rotors and/or systems with compressor drying.

An optimal suitable system is e.g. the kolb PSE 300 HD single tank economy system for stencil cleaning. Further suitable systems are available on request or result from corresponding analyses of your specific paint stripping requirements.

The cleaning time e.g. in a PSE300 HD system with kolb MultiEx® N7 neutral cleaner as cleaning and rinsing medium is approx. 30 minutes. With a higher equipped system this time can be shortened even more.

CarrierSeal® is ESD-safe (on ESD-safe surfaces), biodegradable and does not contain microplastics.

Sealing of the coating substrate with CarrierSeal®

Sealing of machine parts prior the coating process

Removal of the sealing and process destabilizing coating residues

Option: Machine cleaning of the sealing in a carrier-washing frame

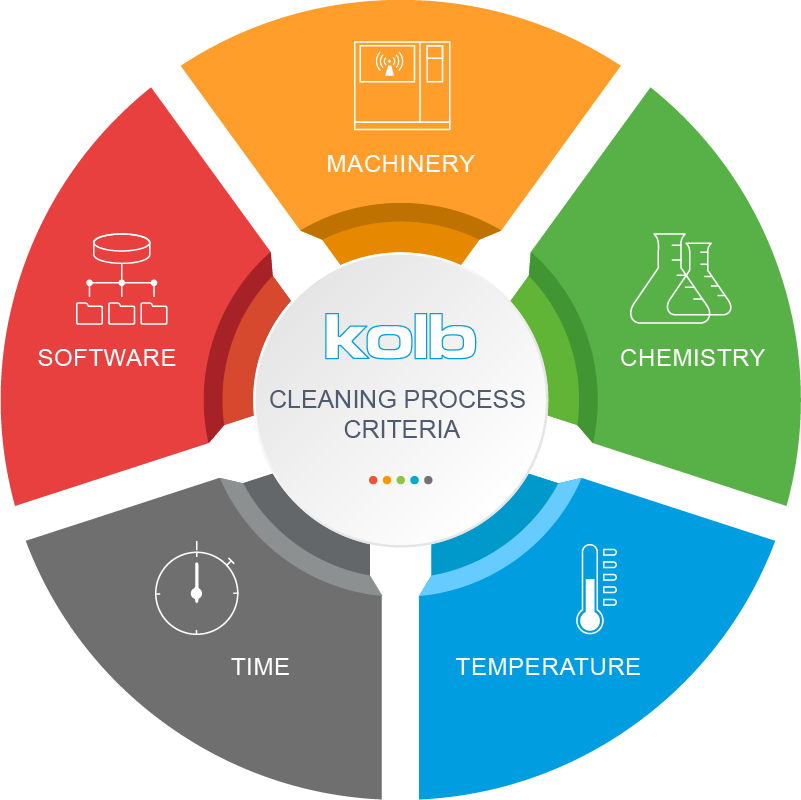

Which technology is the fastest and most cost-effective for you depends on a number of factors that need to be considered carefully before implementing a process chain. The first step is to define the product parameters (paint properties, material properties, degree of contamination, etc.) in order to then optimally design and set up the machinery process comprising machine, chemistry, temperature, time and software.

The aim is to remove coating residues from tools and machine parts as quickly as possible with a minimum of personnel and manual work and to have them ready for use again.

Our qualified and well-equipped technical centre and analytical laboratory will help you to achieve this. Make an appointment with us at any time at info@kolb-ct.com or by phone: +49 2154 9479-65.

Meet us and our partner A-Tek Systems Group in Anaheim!

Read more »