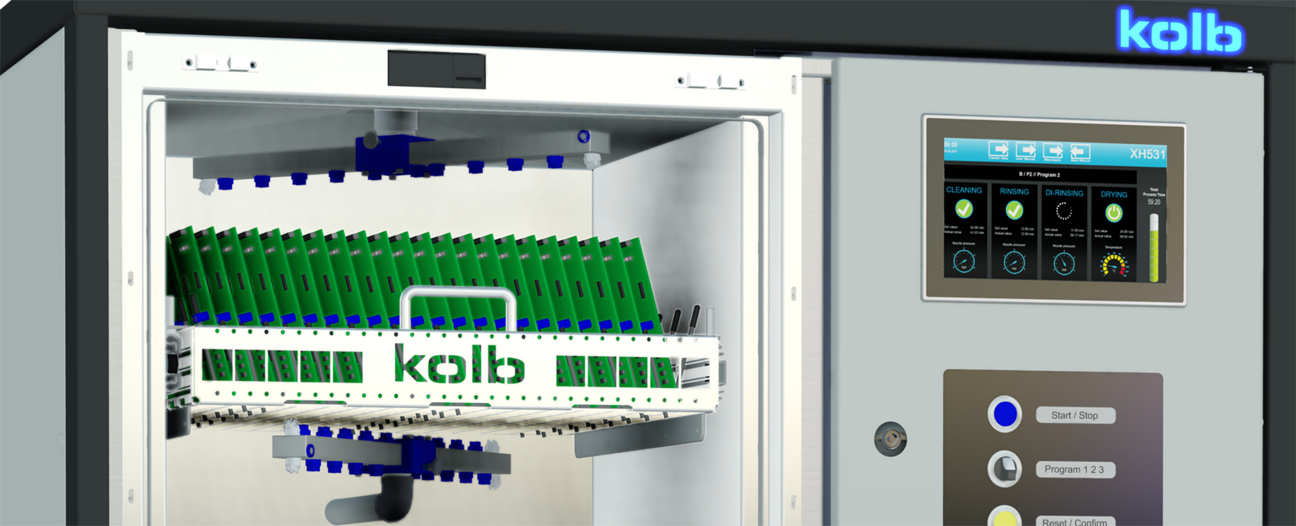

AQUBE® XH5

Fully automatic high end batch cleaner for assembled PCBs

The kolb AQUBE® series offer next-generation cleaning systems - even more efficient, even more compact, easy to handle and maintain, pre-equipped for extended water management and ready for the smart factory (SF ready certified).

AQUBE® XH5 is a fully automatic new generation PCB ultra-fine cleaning systemwith a capacity of up to 176 (2.8 m²/ 30 ft²) eurocards.

AQUBE® XH5 is a German engineered and manufactured machine primarily for the process safe fine cleaning of assembled PCBs, hybrids (HDIs, SiPs) and misprints from reflow flux residues, resin, copper, oxide and soldering support substances.

The parallel working three-tank, three-circuit configuration with ClosedLoop water reprocessing ensures short cycle times as well as low running cost leading to an uncontested low total cost of ownership value.

Highlights

- Three tank system with three separate circuits

- Smart Factory ready: DNAccess, remote control, traceability (PLC data scanning and memorizing)

- Fully automatic 4step (optional up to 5step) process: cleaning, (MediumWipe®), rinsing (tap water), DI-water rinsing, drying with VMH®-TurboDigital hot air

- Horizontal PTFE mounted rotor system with up to four asynchronous spray rotors for thorough wetting (no blind spots)

- Heater cleaning tank A, automatic water change for the rinsing circuit, DI water system, DI-bypass processing, water measuring unit (ion contamination measurement), ion exchanger and fine filter systems as standard

- Processes and service intervals PLC controlled. Event issuing and software control via touch screen

- EDGELESS Design and VARIccess® service access: maximum capacity, easy maintenance on a very small footprint

- Suitable for high temperature cleaning and rinsing up to 80 °C (176 °F)

Technical data | |

|---|---|

| Technology base | kolb PowerSpray® |

| Control system (Display size) | PLC - Eaton (10“) |

Standard capacity (per process cycle)

| 176 (2.8 m²/30 ft²) eurocards |

| Process chamber dimensions | W 540 mm • D 590 mm • H 570 mm |

| Max. number washing baskets | 2 |

| Washing basket size | 470 mm x 470 mm |

| Circuits | 3 Cleaning, Rinsing tap water, Rinsing DI-water |

| Volume Tank A | 55 l • Cleaning |

| Volume Tank B | 35 l • Rinsing tap water |

| Volume Tank C | 35 l • Rinsing DI-water |

| Max. cleaning temperature | 80 °C (176 °F) |

| Filtration | Up to four stages - 1. Full flow coarse filter < 2mm (0.08"), 2. Sediment filter inside the tank, 3. 20“ fine filter (1 - 100 µm - process dependent), 4. HMA filter |

| Drying System | VMH®-TurboDigital hot air |

| Drying temperature range | approx. 45 - 120 °C (113 and 248 °F) |

| Power supply | 400 V AC, 16 A, CEE plug / 3 Ph / 50 or 60 Hz |

| Power consumption | 4 kW |

| Supply connection 1 (tap water) | 1/2“ |

| Supply connection 2 (DI water) | 1/2“ |

| Supply connection 3 (Compressed Air) | 8 mm (87 - 116 psi - 100 l / min) |

| Empty Weight | 350 kg (772 lbs) |

| Footprint | 840 mm x 1180 mm (33.07″ x 46.46″) |

Certifications

Downloads

back