Cleaning of stencil undersides / flipsides

kolb offers as a manufacturer and specialist for cleaning in the electronics producing industry aqueous, ph-neutral special detergents for the thorough cleaning of stencils undersides inside a screen printer.

In addition to machine cleaning of the entire stencil, cleaning the underside or reverse side of the stencil directly in the printer is an important factor for reproducible, error-free printing results.

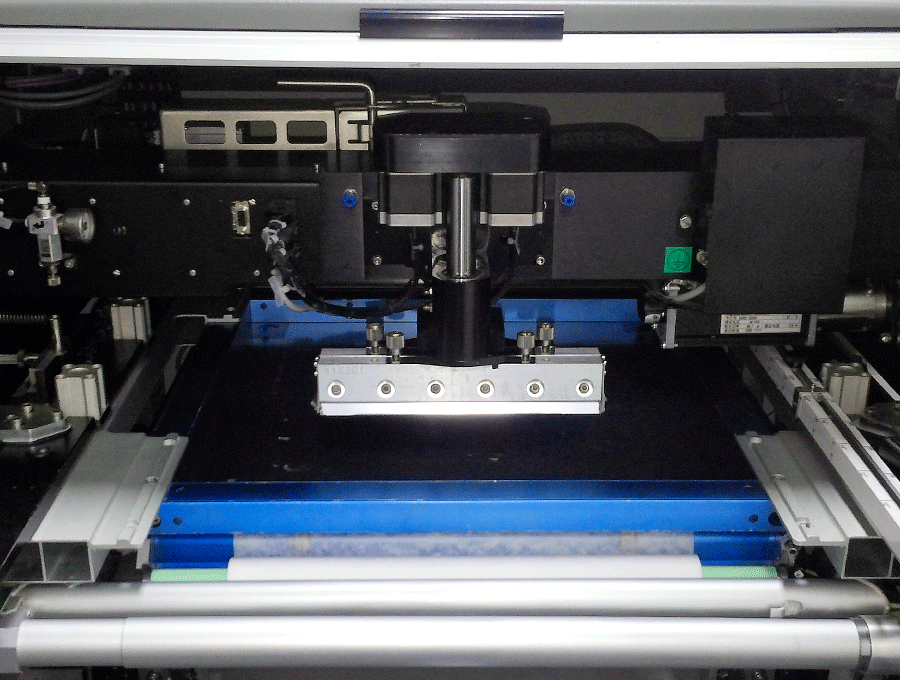

In printer-internal stencil cleaning, paste or adhesive residues are removed by wiping, with wet- or dry-cleaning cloths. The cleaning detergent for wet cleaning is applied either via a porous stone or by means of a moving nozzle.

To achieve an optimum result, only special cleaning agents, preferably aqueous, should be used which do not affect the viscosity of the solder paste. The viscosity of the detergent should ensure efficient tissue wetting and (in contrast to e.g. volatile, alcohol-based detergents) ensure ecological and economic advantages.

Nevertheless, to ensure high reliability, it is necessary that the stencils are removed at a steady frequency and then washed. Preferably this process is carried out in an automatic stencil cleaning system, to thoroughly clean the apertures. Only manually wiping the stencils would only push the residual paste back into the apertures - similar to the effect of a squeegee.