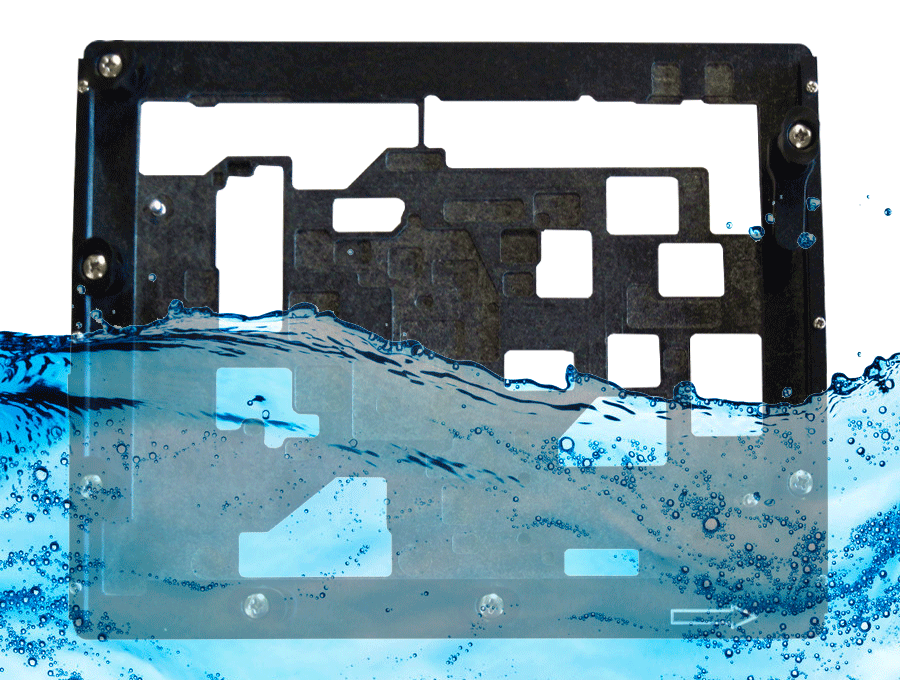

Cleaning of solder pallets

As a manufacturer and system supplier kolb provides for the cleaning of solder pallets the complete process from a single source: including machinery, accessories, detergents and specially applied software controlled, fully automated electronic processes.

An important element of process stability in electronics manufacturing is maintenance cleaning. Solder pallets, frames, carriers, masks as well as condensate traps, filters, coolers, reflow ovens, wave soldering systems - all these components and parts must be thoroughly cleaned on a regular basis to ensure process stability.

The main task here is the removal of burnt-in fluxes as well as the removal of rosin from solder masks, solder frames and carriers. Preferably, cleaning is carried out with fully automatic cleaning systems and environmentally friendly, water-based detergents.

Suitable cleaning systems

PSE MH5

Economy tools cleaning system especially for solder carriers, pallets, trays

Capacity: 7 carriers up to 480 x 430 mm (19“ x 17“), boxes / racks up to 540 x 590 x 570 mm or up to two drawer baskets for small parts, filters etc.Horizontal spray rotor system, VMH®-Turbo evaporative drying

Process chamber dimensions: W 540 • D 590 • H 570 mm (W 21.25" • D 23.22" • H 22.44")

more about PSE MH5

PSE MH7

Fully automatic XL tools and maintenance economy cleaning system

Capacity: 11 carriers up to 670 x 640 mm (26“ x 25“), boxes / racks up to 700 x 720 x 710 mm or up to three drawer baskets for small parts, filters etc.Horizontal spray rotor system, VMH®-Turbo evaporative drying

Process chamber dimensions: W 700 • D 720 • H 710 mm (W 27.55" • D 28.34" • H 27.95")

more about PSE MH7

AQUBE® MH5

Tools cleaning system especially for solder carriers, pallets, trays

Capacity: 7 carriers up to 480 x 430 mm (19“ x 17“), boxes / racks up to 540 x 590 x 570 mm or up to two drawer baskets for small parts, filters etc.Horizontal spray rotor system, VMH®-Turbo evaporative drying

PolyPower® Technology (up to three times more pressure power and up to 30% less cycle time)

Process chamber dimensions: W 540 ▪ D 590 ▪ H 570 mm (W 21.25" ▪ D 23.22" ▪ H 22.44")

more about AQUBE® MH5

AQUBE® MH7

Fully automatic XL tools and maintenance cleaning system

Capacity: 11 carriers up to 670 x 640 mm (26“ x 25“), boxes / racks up to 700 x 720 x 710 mm or up to three drawer baskets for small parts, filters etc.Horizontal spray rotor system, VMH®-Turbo evaporative drying

PolyPower® technology (up to three times more pressure power and up to 30% less cycle time)

Process chamber dimensions: W 700 • D 720 • H 710 mm (W 27.55" • D 28.34" • H 27.95")

more about AQUBE® MH7

AQUBE® MH9

Fully automatic XXL allround tools cleaning system with super large process chamber

Capacity: 14 carriers up to 950 x 750 mm (37.5“ x 29.5“), boxes / racks up to 970 x 955 x 900 mm or up to four drawer baskets for small parts, filters etc.Horizontal spray rotor system, VMH®-Turbo evaporative drying

Process chamber dimensions: W 970 • D 955 • H 900 mm (W 38.18" • D 37.59" • H 35.43")

more about AQUBE® MH9

Suitable detergents

MultiEx® A12

Broadband detergent most suitable for solder carriers, solder pallets, ESD boxes, PCB storage magazines and PCBAs

Aqueous alkaline detergent for use in kolb systems with PowerSpray® and AirFlow® technology as well as in any common spray-in-air and spray-in-immersion cleaning system. Most suitable for solder carriers, solder pallets, ESD boxes, PCB storage magazines and PCBAs

MultiEx® A12

ContraFlux® Basic

ContraFlux® Basic is an aqueous alkaline cleaning detergent for kolb AirFlow® or common spray-in-immersion cleaning systems. Suitable for solder carriers, solder pallets, ESD boxes, PCB magazines, condensation traps.

ContraFlux® Basic

ContraFlux® BC

Detergent for ESD boxes, PCB magazines, solder carriers, solder pallets

ContraFlux® BC is an aqueous alkaline cleaning detergent for use in kolb systems with PowerSpray® and AirFlow® technology as well as common spray-in-air and spray-in-immersion cleaning systems. Most suitable for solder carriers, solder pallets, ESD boxes, PCB magazines

ContraFlux® BC

CF1®

Aqueous alkaline ReadyMix for the manual cleaning of reflow ovens

CF1® is an highly effective detergent for SMD reflow ovens, wave solder equipment, carriers and machine parts.

CF1®

G50®

Aqueous alkaline intensive ReadyMix for manual oven cleaning

G50® is an aqueous intensive cleaner for particularly consistent contamination of SMD reflow ovens, wave solder equipment, carriers and machine parts.

G50®