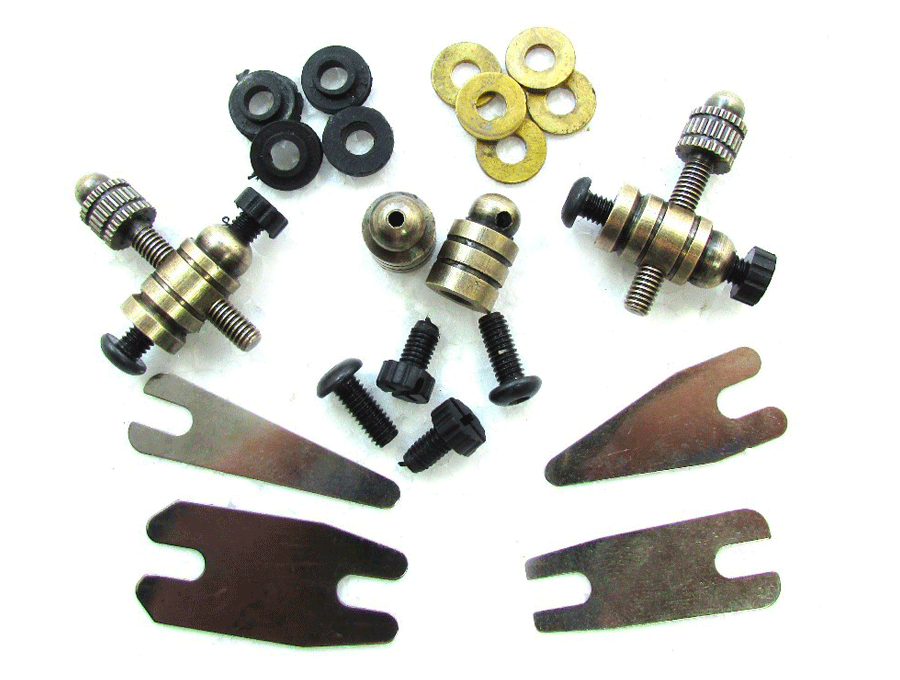

Cleaning of machinery parts and tools

As a manufacturer and system supplier kolb provides for the cleaning of machinery parts and also medical (e.g.instruments, containers) and industrial parts (e.g.bulk, milling parts, complex parts) the complete process from a single source: including machinery, accessories, detergents and specially applied software controlled, fully automated electronic processes.

Machine parts that become contaminated in the production process due to deposits of condensate, flux, rosin, grease, dust and oil, and thus jeopardize error-free reproducibility of production processes, must be cleaned regularly and thoroughly. The same applies, for example, to turned and milled parts from prefabrication.

In addition to cleaning machine parts from electronics manufacturing, maintenance cleaning, systems and detergents from kolb are also ideal for cleaning medical or industrial parts - either to disinfect products or to remove production residues and thus ensure the quality of downstream processes or the cleanliness of end products.

Suitable cleaning systems

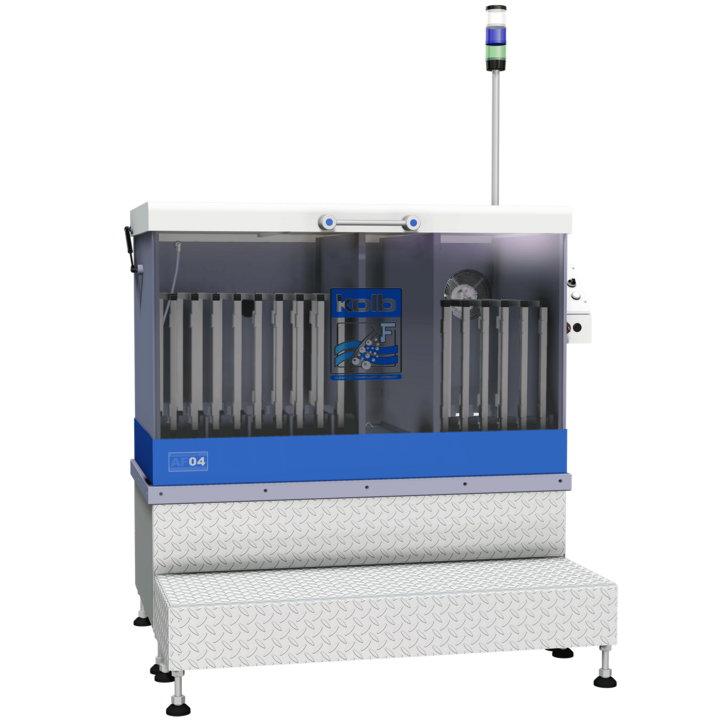

AF04

Semi-automatic three chamber system for various maintenance cleaning tasks

Semi-automatic three chamber system with AirFlow® turbulence air-in-immersion technologyCleans: Cleans carriers, pallets and condensation filters and machine parts

Usable process chamber dimensions (cleaning): W 580 • D 610 • H 470 mm

Usable process chamber dimensions (Rinsing): W 200 • D 610 • H 470 mm

Usable process chamber dimensions (Drying): W 380 • D 610 • H 470 mm

more about AF04

AF20

Fully automatic air-in-immersion system for maintenance cleaning

Fully automatic system with AirFlow® turbulence air-in-immersion technologyCleans: Condensation traps, solder-frames, carriers and machine parts

Usable process chamber dimensions: W 800 • D 430 • H 500 mm

more about AF20

AF30

Fully automatic air-in-immersion system for maintenance cleaning

Cleaning in the entire chamber with AirFlow® air-in-immersion technologyCleans: Condensation traps, solder-frames, carriers and machine parts

Usable process chamber dimensions: W 1,300 • D 450 • H 590 mm

more about AF30

AF75

Fully automatic large-scale air-in-immersion system for maintenance cleaning

Large maintenance cleaning device with crane loading Cleans: Condensation traps of virtually all manufacturers as well as carriers, solder frames and pallets

Usable process chamber dimensions: W 705 • D 915 • H 510 mm

more about AF75

PSE MH6

Fully automatic economy cleaning system for solder frames, solder carriers, solder pallets, ESD boxes, PCB magazines, trays, machinery parts

Capacity: 7 carriers up to 610 x 490 mm (24" x 19") or up to three washing drawersHorizontal spray rotor system

Process chamber dimensions: W 540 • D 590 • H 710 mm (W 24.26" • D 23.23" • H 27.95")

more about PSE MH6

PSE MH7

Fully automatic "all-round" economy tools and parts cleaning system

Capacity: 11 carriers up to 610 x 640 mm (24“ x 25“), boxes / racks up to 640 x 640 (25" x 25") mm or up to three drawer baskets for small parts, filters etc.Horizontal spray rotor system, VMH®-Turbo evaporative drying

Process chamber dimensions: W 700 • D 720 • H 710 mm (W 27.55" • D 28.34" • H 27.95")

more about PSE MH7

AQUBE® MH6

Fully automatic "all-round" tools and parts cleaning system

Capacity: 7 carriers up to 610 x 490 mm (24" x 19") or up to three washing drawersHorizontal PTFE-mounted rotor system with ASYNCHRON® spray rotors for thorough wetting (no blind spots)

Process chamber dimensions: W 540 ▪ D 590 ▪ H 710 mm (W 24.26" ▪ D 23.23" ▪ H 27.95")

more about AQUBE® MH6

AQUBE® MH7

(also available as AQUBE® MH7 TZD)

Fully automatic "all-round" tools and parts cleaning system

Capacity: 11 carriers up to 610 x 640 (24" x 25") or 640 x 640 mm (25" x 25") or up to three washing drawersHorizontal spray rotor system, VMH®-Turbo evaporative drying

PolyPower® technology (up to three times more pressure power and up to 30% less cycle time)

Process chamber dimensions: W 700 • D 720 • H 710 mm (W 27.55" • D 28.34" • H 27.95")

more about AQUBE® MH7

AQUBE® MH9

Superlarge fully automatic "all-round" tools and parts cleaning system

Capacity: 28 carriers up to 750 x 950 mm (29.5" x 37.5") using the washing cart use or up to four washing drawersHorizontal spray rotor system, VMH®-Turbo evaporative drying

Process chamber dimensions: W 970 • D 955 • H 900 mm (W 38.18" • D 37.59" • H 35.43")

more about AQUBE® MH9