Cleaning of DCBs & ceramic substrates (power electronics)

As a manufacturer and system supplier kolb provides for the cleaning of DCBs, ceramic cubstrates and hybrids the complete process from a single source: including machinery, accessories, cleaners and specially applied software controlled fully automated electronic processes.

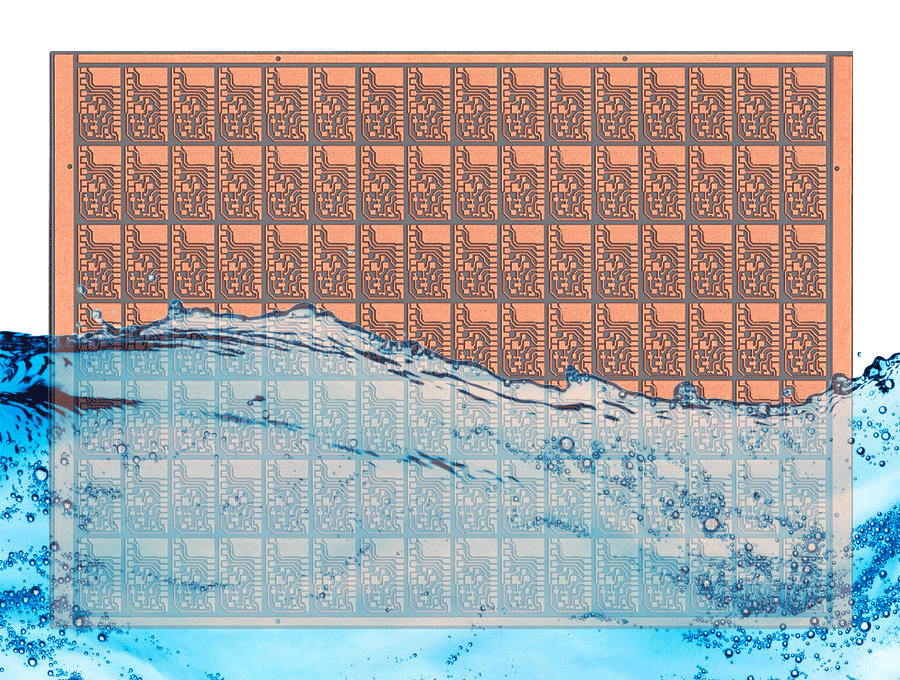

Direct copper bonding (DCB) substrates are often used due to their good thermal conductivity in high-performance modules. They consist of a ceramic substrate board, usually alumina or aluminum nitride and usually applied with a copper foil on one or both sides in a high temperature oxidation process. Precisely because of the high power requirements (DCB substrates carry currents up to several thousand volts at temperatures up to 200° C), these components must be absolutely free of production residues for further working processes such as wire bonding, coating or varnishing.

Thorough removal of flux, rosin, resin, Cu oxide and soldering support substances are the main tasks in the cleaning of DCBs, hybrids, assemblies / assembled printed circuit boards, in order to be able to offer correspondingly process-safe assemblies for the above mentioned subsequent processes.

Suitable cleaning systems

AQUBE® XH7

Fully automatic high end XL batch cleaner for assembled PCBs

Capacity: up to 540 (8.6 m² / 92.5 ft²) standard eurocards in up to three variable drawer basketsPolyPower® Technology (up to three times more pressure power and up to 30% less cycle time)

Horizontal up to sixfold spray rotors, VMH® TurboDigital evaporative drying

Process chamber dimensions: W 700 • D 720 • H 710 mm (W 27.55" • D 28.34" • H 27.95")

more about AQUBE® XH7

AQUBE® XH9

Fully automatic high end batch cleaner with largest process chamber worldwide

Capacity: up to 830 standard eurocards equals 19 m² (204.5 ft²) in up to four variable drawer baskets Horizontal up to eightfold spray rotors, VMH®-TurboDigital evaporative drying

Process chamber dimensions: W 970 • D 955 • H 900 mm (W 38.18" • D 37.59" • H 35.43")

more about AQUBE® XH9

Suitable detergents

MultiEx® 3D-A3

Special cleaner for power electronics / DCBs

Removes copper oxides / CuO, aluminium oxides, SMD paste, fluxes, solder pastes (soldered) from DCBs, PCBAs, ceramic substrates, aluminium, non-ferrous metals.

MultiEx® 3D-A3

MultiEx® 3D-H2

broadband cleaner for PCBAs especially with large metal surfaces

Removes SMD paste, rosin flux, fluxes, copper oxides / CuO, aluminium oxides from PCBAs, DCBs, ceramic substrates, aluminium, non-ferrous metals.

MultiEx® 3D-H2

MultiEx® NP-1

Multifunctional pH-neutral detergent especially for PCBAs and power electronics

Aqueous, pH-neutral broadband cleaner especially for PCBAs and power electronics for the removal of flux and solder pastes.

MultiEx® NP-1

MultiEx® VR-HPA

Highend broadband cleaner for PCBAs with sensitive components

Removes fluxes and pastes especially from PCBAs with sensitive components, from ceramic substrates, misprints, stencils, solder carriers, solder pallets, ESD boxes, PCB magazines.

MultiEx® VR-HPA