Cleaning of condensate filters, traps, cyclons, heatsinks

As a manufacturer and system supplier kolb provides for the cleaning of condensate traps, filters, coolers, cooling plates, heatsinks, cyclones etc. the complete process from a single source: including machinery, accessories, detergents and specially applied software controlled, fully automated electronic processes.

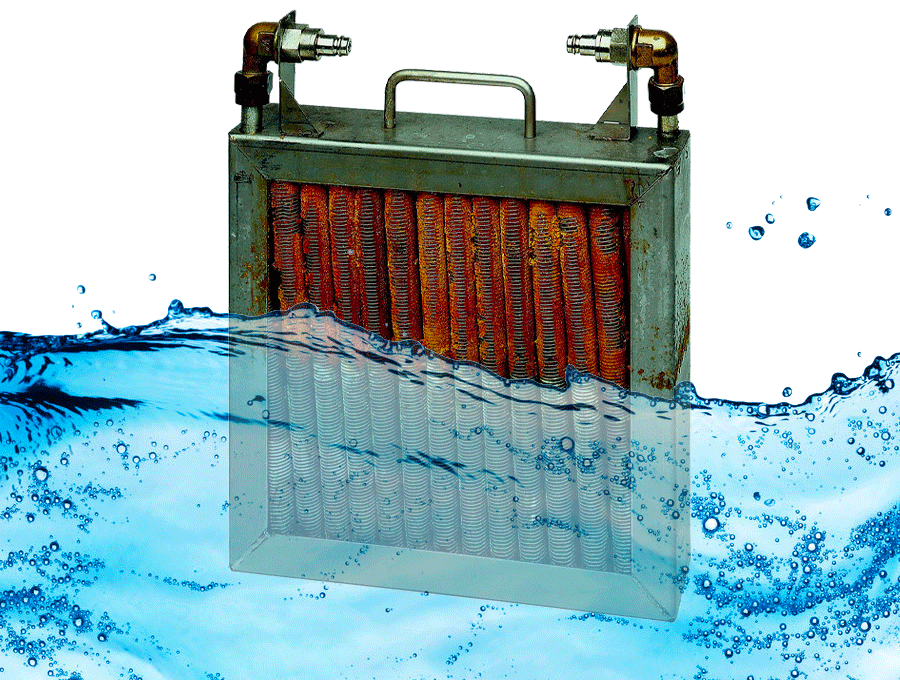

Condensate traps, filters, recirculating chillers, cyclones, fluxer plates, reflow ovens, wave and selective soldering systems - all these components must be cleaned regularly and thoroughly to maximize productivity. This includes, in particular, the cleaning of condensate management modules specifically installed for the collection of condensate components, such as condensate filters and cooling traps in the zone transitions and cooling zones of reflow, selective and inert gas wave soldering systems.

The atmosphere of a soldering system contains many substances that must not be allowed to condense in the process chamber because they lead to cross-sectional changes and thus to changes in the air flow conditions.

In order to be able to separate these substances in a targeted manner, part of the process atmosphere is continuously extracted and passed through separation systems and filters. The cleaned atmosphere is then fed back into the process. This complex system is known as condensate management.

Condensate traps, condensate filters, condensate separators / cyclones are central components of a condensate management system. They remove condensable substances from the gas flow and ensure process gas cleaning, thus a clean process chamber and in turn a stable process. This is particularly important when using lead-free solders in nitrogen systems.

Suitable cleaning systems

AF20

Fully automatic one chamber system for all maintenance cleaning tasks

Fully automatic system with AirFlow® turbulence air-in-immersion technologyCleans: Condensation traps, solder-frames, carriers and machine parts

Usable process chamber dimensions: W 810 • D 435 • H 520 mm

more about AF20

AF30

Fully automatic one chamber XL system with AirFlow® technology

Cleaning in the entire chamber with AirFlow® air-in-immersion technologyCleans: Condensation traps, solder-frames, carriers and machine parts

Usable process chamber dimensions: W 1.300 • D 450 • H 600 mm

more about AF30

AF75

XXL AirFlow® system for the bulk cleaning of condensation filters and coolers

Large maintenance cleaning device with crane loading Cleans: Condensation traps of virtually all manufacturers as well as carriers, solder frames and pallets

Usable process chamber dimensions: W 770 • D 1.280 • H 600 mm

more about AF75

Suitable detergents

ContraFlux® FM

Special detergent for the removal of condensate residues

ContraFlux® FM is an aqueous alkaline cleaning detergent for use in kolb cleaning systems with AirFlow® technology or common spray-in-immersion cleaning systems. Most suitable for condensation traps, condensation filters, coolers, cyclones

ContraFlux® FM

StoveEx®

Extra strong aqueous detergent concentrate for maintenance cleaning

StoveEx® is an extra strong aqueous alkaline cleaning detergent concentrate for stubborn and burnt stains, epoxy resins and condensates.

StoveEx®