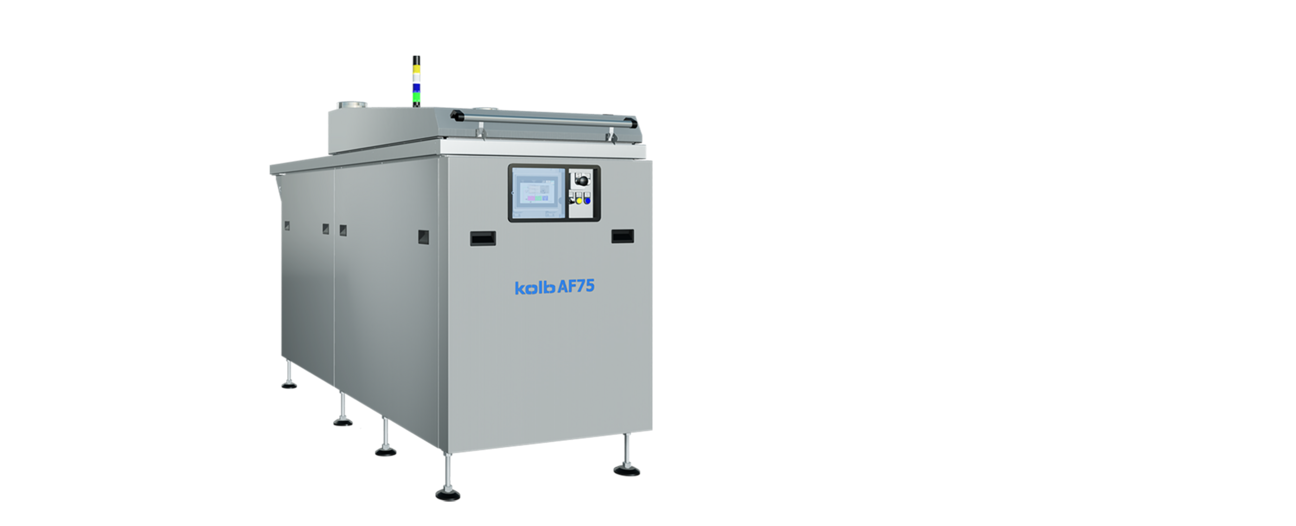

AF75

For the mass cleaning of condensation filters of virtually all manufacturers, carriers from flux, condensate, oil, dust, grease

kolb AF75 is a state of the art one chamber system with the economic and environmentally friendly AirFlow® air-in-immersion technology and ClosedLoop water reprocessing. The device is especially designed for the bulk cleaning of condensation traps and filters. It cleans traps of virtually all manufacturers from condensate from flux, oil, dust, grease.

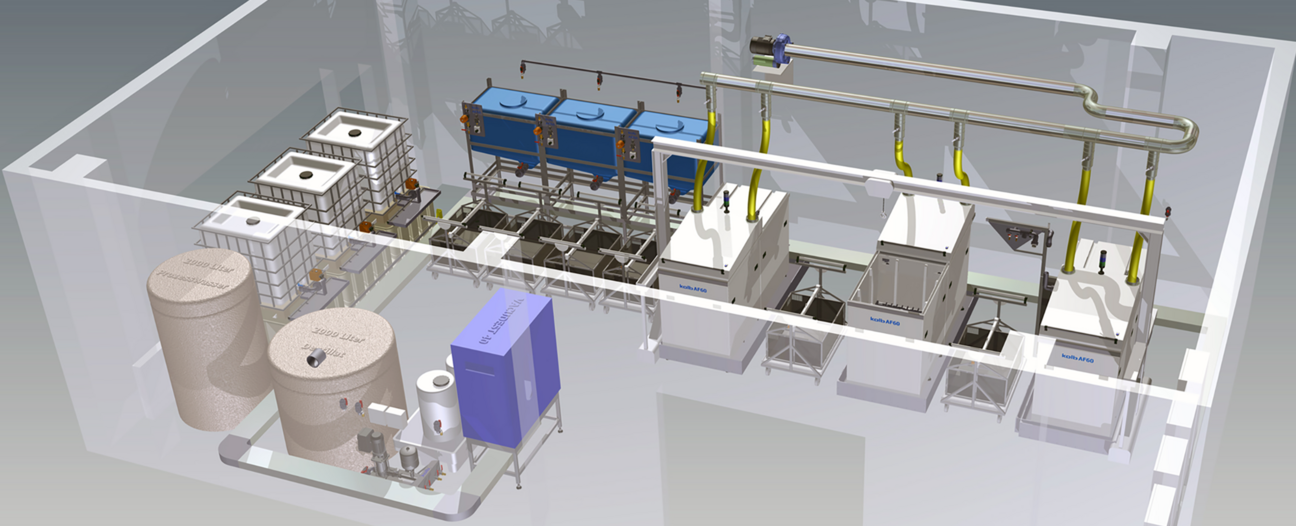

Up-to-date reflow-soldering systems as well as solar process ovens usually have flux management systems (cooling unit, filters, heat exchanges, containers/plates) which during operation will be subject to contamination (with flux/raisin). Thorough cleaning helps to regain proper functioning. The system is (in series use) perfectly suited for the construction of complete washing centers that comply with the latest technical state of the art and can deliver extremely high throughput quantities.

Highlights

- Single-chamber system with automatic operation: cleaning, rinsing, drying

- Average process time: 60 min

- Loading and unloading in an empty process chamber (no contact to detergent)

- Control unit in switch cabinet on the rear side

- Processes and service intervals PLC controlled

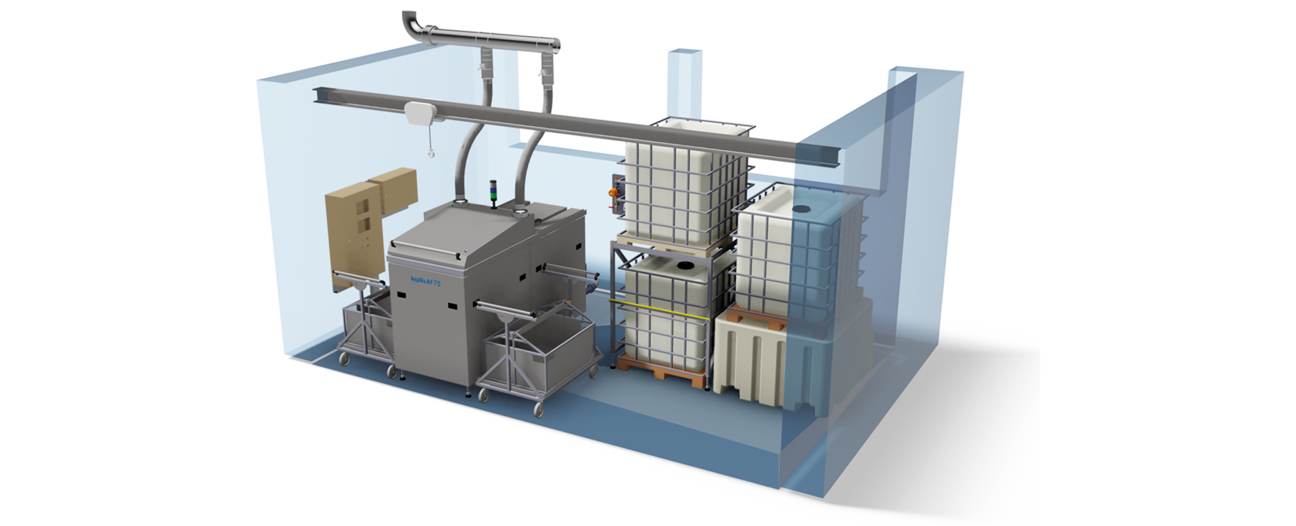

- External 1,000 l IBC releasing containers for cleaning and rinsing fluid

- Re-dosage directly from the IBC container

- External cleaning of cyclones and oven tubings possible

Technical Data (Excerpt) | |

|---|---|

| Technology base | kolb AirFlow® |

Standard capacity (per process cycle)

| Condensation traps, filters, carriers, solder frames and pallets up to 770 x 1,280 x 600 mm |

| Process chamber dimensions | W 1280 mm • D 770 mm • H 600 mm |

| Max. stencil, carrier, washing frame size | H 770 mm x W 1280 mm |

| Circuits | 2: Cleaning, Rinsing |

| Volume Tank A (Cleaning) | 1000 l |

| Volume Tank B (Rinsing) | 1000 l |

| Max. cleaning temperature | 65 °C (149 °F) |

| Filtration | up to three stages - 1. Full flow coarse filter < 2 mm (0.08"), 2. Skimmer coarse filter, 3. Fine filter 20“ / 100 - 50 - 10 µm in the circuits |

| Drying System | CTS HotSpeed warm air |

| Drying temperature range | approx. 55 - 60 °C (131 and 140 °F) |

| Footprint | 2360 mm x 940 mm (92.91″ x 37.01″) |

Certifications

Downloads

back