What should be noted concerning cleaning of misprints?

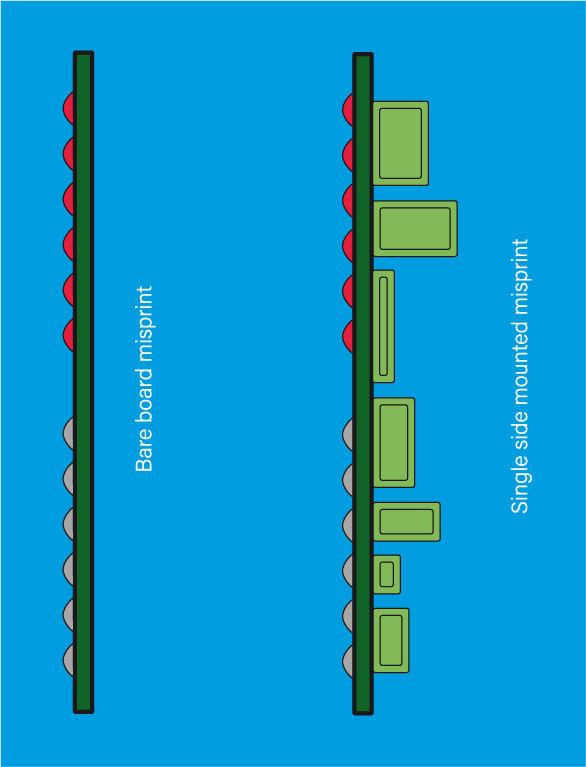

There are different cleaning requirements for bare board vs. single side mounted misprints.

A misprint is a printed circuit board side which is faulty printed with solder paste or adhesive or is declared as faulty for other reasons.

Misprint cleaning should generally be carried out in cleaning systems with a vertical rotor arrangement. In vertical cleaning, the cleaning good is usually wetted directly by the spray jets, so that there is also optimum mechanical pressure of the cleaning fluid on the vias. - This in turn is useful because in the event of a printing error, paste/glue has usually been incorrectly applied to the vias. Cleaning with a horizontal rotor arrangement is not recommended for misprints, since here the cleaning jet usually hits the cleaning good with less mechanical energy. Furthermore, when cleaning with a horizontal system, cross-contamination of paste on the horizontally placed PCBAs must be expected.

The cleaning of a printed bare circuit board is subject to the requirements similar to stencil cleaning. Stencil cleaning systems are usually equipped with vertical rotors and are therefore perfectly suited for cleaning misprinted bare boards. The cleaning time is approx. the same as for a stencil and can be carried out quickly and easily after testing and approval in a qualified process using a stencil cleaning system.

However, if one side of the misprint is already loaded with active components which are already soldered, it is subject to the cleaning requirements of an assembled circuit board. In this case it is recommended to clean such an "assembly misprint" in a suitable vertical cleaning system which is also qualified forPCBA cleaning. (e.g. kolb PSE300-2VL, AQUBE MV8 or similar).

Paste or adhesive of the misprinted side could still be cleaned in a "misprint cleaning time". The backside assembly would, however, in this time only be partially cleaned, i.e. the soldered flux / rosin would not be completely removed from the components. In this case, the partially cleaned respectively cracked flux could lead to product errors.

For this reason, the cleaning time for the misprint on a circuit board that has already been mounted on one side is approximately the same as in the case of a finished, correct assembly. It is generally carried out with a special PCB cleaning detergent and with a two-stage water, DI / DM water rinse process in a qualified PCB cleaning system. The drying of the assembly is also more complex than that of a bare board misprint due to the scoops and intermediate spaces and therefore also requires suitable drying.