White Papers

Explore in-depth information on selected topics related to cleaning.

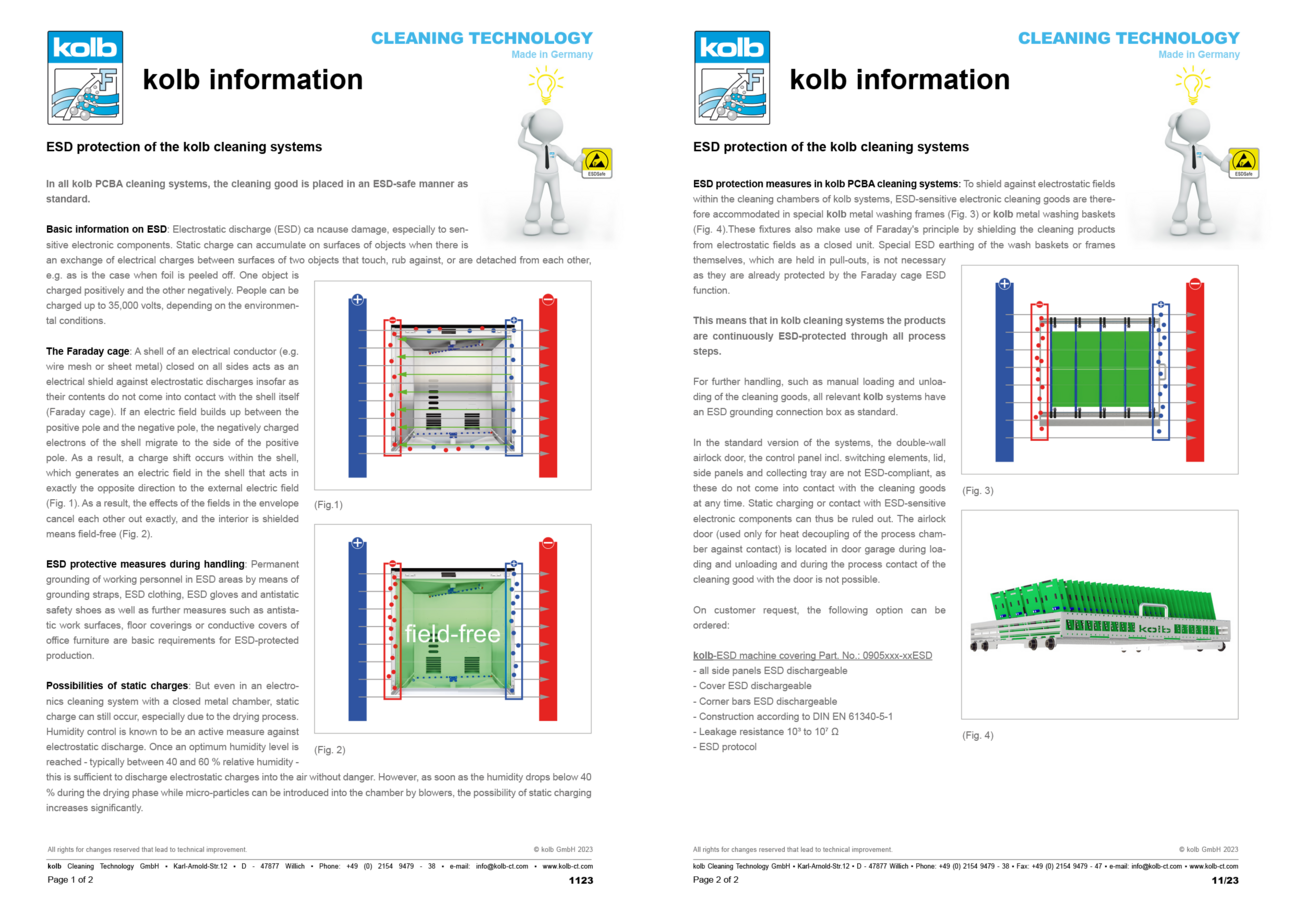

About ESD-protection of cleaning systems

Electrostatic discharge (ESD) can cause damage, especially to sensitive electronic components. To shield against electrostatic fields within the cleaning chambers kolb systems are equipped with intelligent fixtures.

Read here how sensitive cleaning goods are ESD-protected kolb cleaning systems.

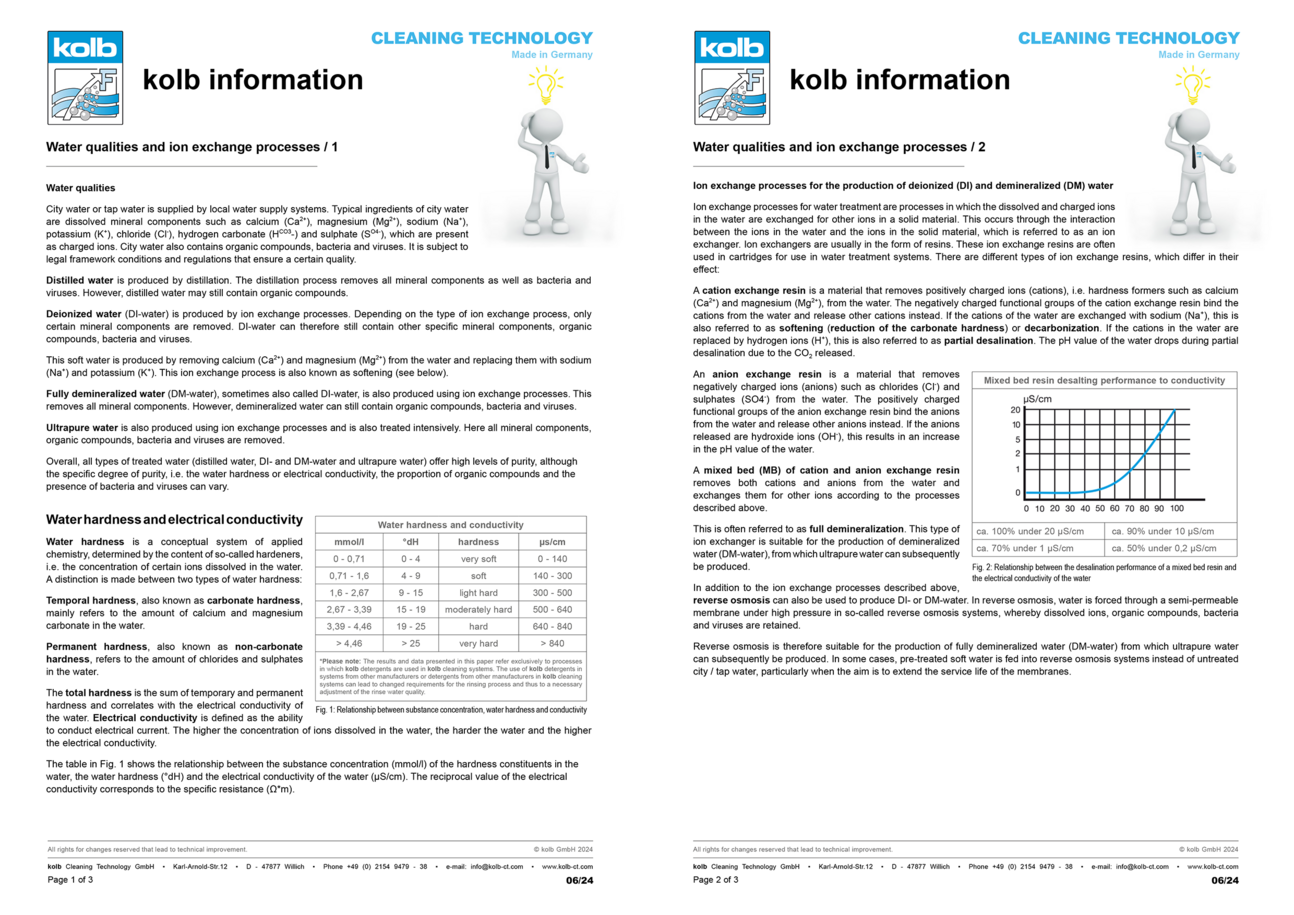

About water qualities and ion exchange

About water qualities, how they can be processed and how they affect the relationship between substance concentration, water hardness and conductivity and thus the cleaning result.

Read here about the different water qualities and ion exchange processes.

About efficient rinsing processes

The current market requirements regarding residual ion contamination levels for a cleaned assembly are typically <1 to 0.6 μg NaCl eq / cm2. Even smaller values can be achieved.

Find out which are the best options to reach these values in the best quality and most economically rinsing process and why an electrical zero conductivity of the rinse water is not necessarily the optimal solution!

About cyclic detergent monitoring

An optimal cleaning result in the electronics cleaning depends to a large extent also on the optimal working ability of the used detergent.

Find out here why a cyclic examination of the cleaning mixture is necessary to measure the current concentration and (if necessary) by post-dosing / adjusting the cleaner to ensure its effectiveness.

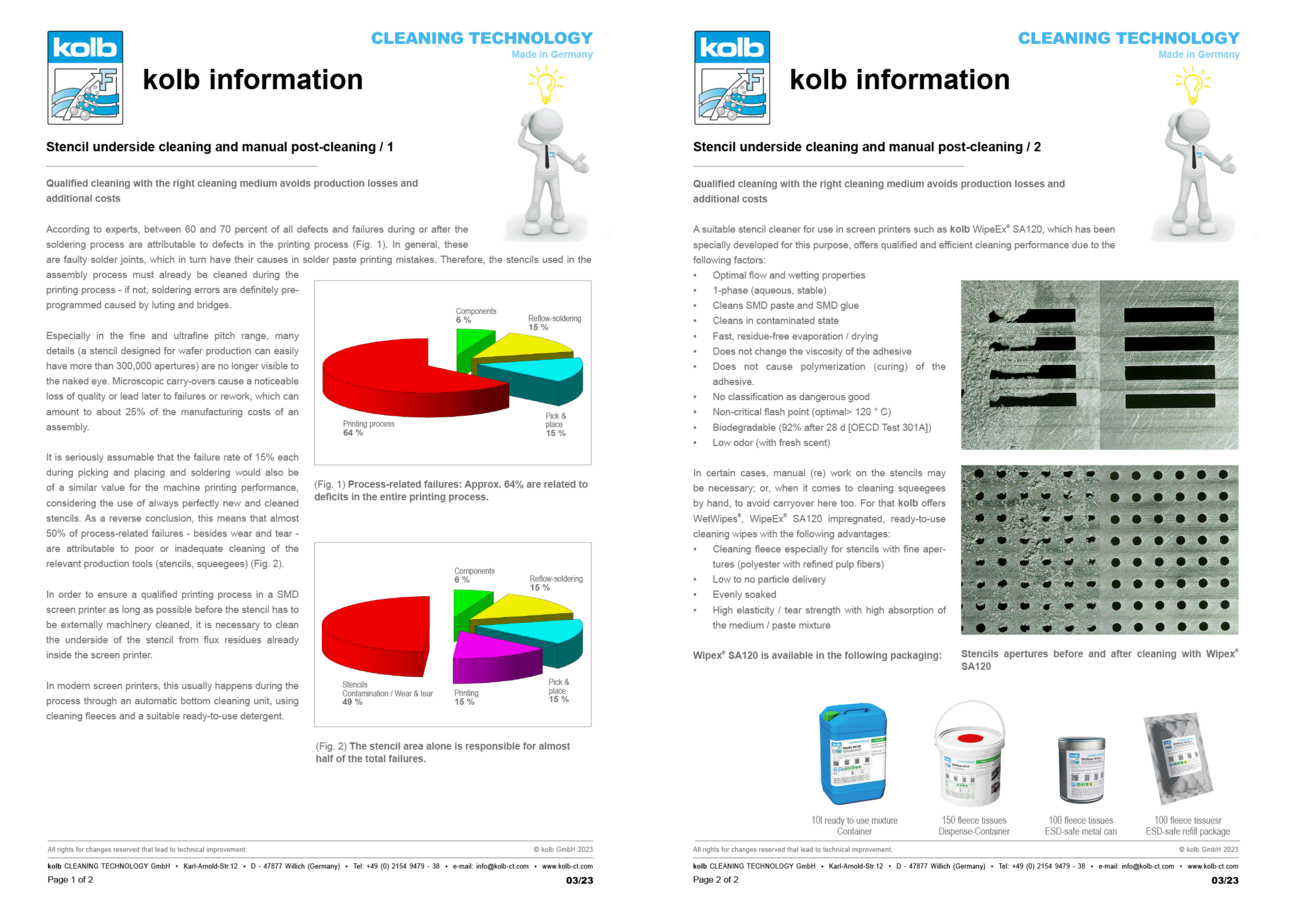

About stencil underside cleaning

According to experts, between 60 and 70 percent of all defects and failures during or after the soldering process are attributable to defects in the printing process - caused in in general by faulty solder joints, which in turn have their causes in solder paste printing mistakes. Find out here how stencil underside cleaning with the right cleaning medium avoids production losses and additional costs.

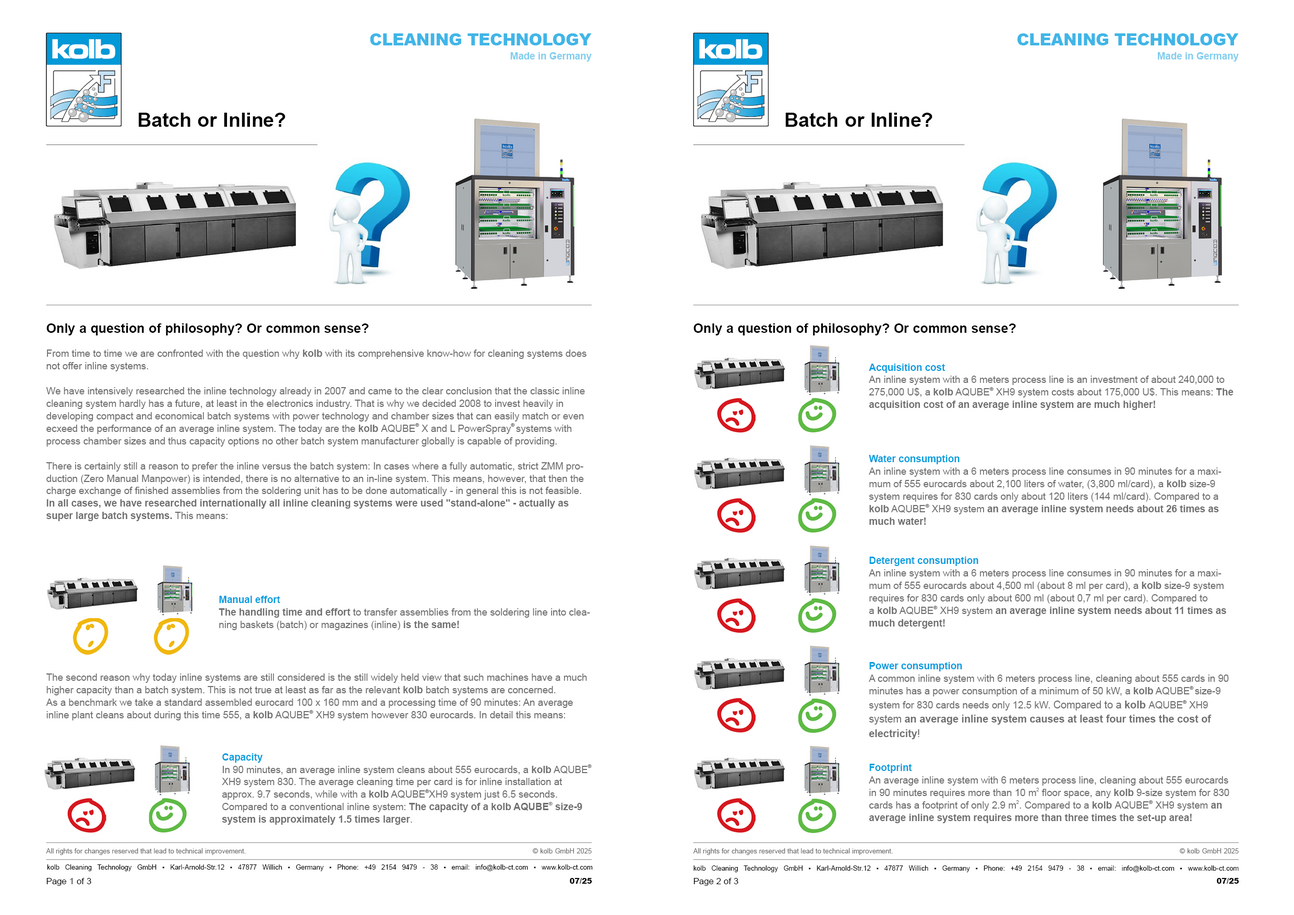

Batch or inline cleaning?

When it comes to cleaning of large volumes of PCBs, the question arises as to whether compact batch systems can handle similar capacities in similar times to large inline systems.

Learn here why the question should actually be the other way around.