Tools cleaning tasks

Tools Cleaning covers the cleaning of all tools that immediately affect the value-added chain. It includes fine cleaning of misprints (bare boards) as well as stencils screens and PumpPrints, but also the maintenance cleaning of carriers, solder frames, filters, tubes, soldering ovens etc.

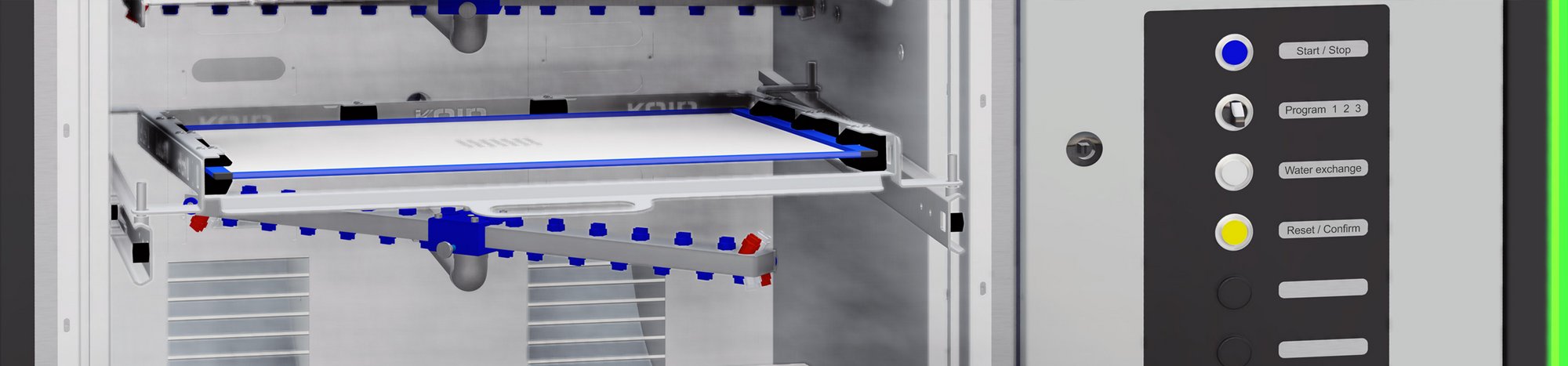

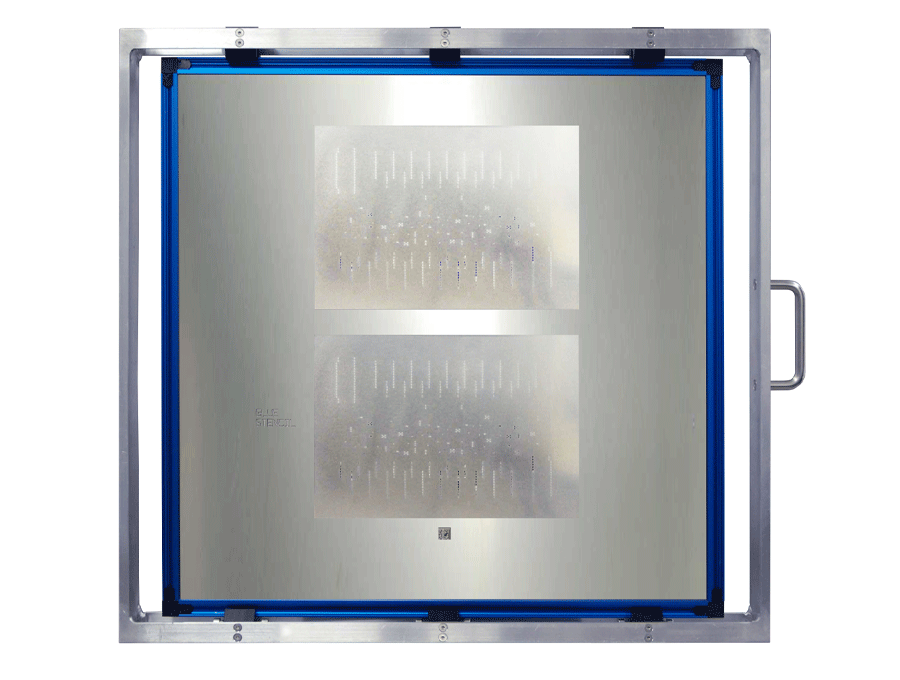

Stencil, screen and misprint cleaning

Optimal cleaning of stencils (framed or frameless stencils)as well as VectorGuard stencils, precision screens and misprints (bare boards) is a must as well in electronics as in the solar industry to assure reproducible quality and low production rejects.

Learn more about stencil cleaning, suitable systems and detergents

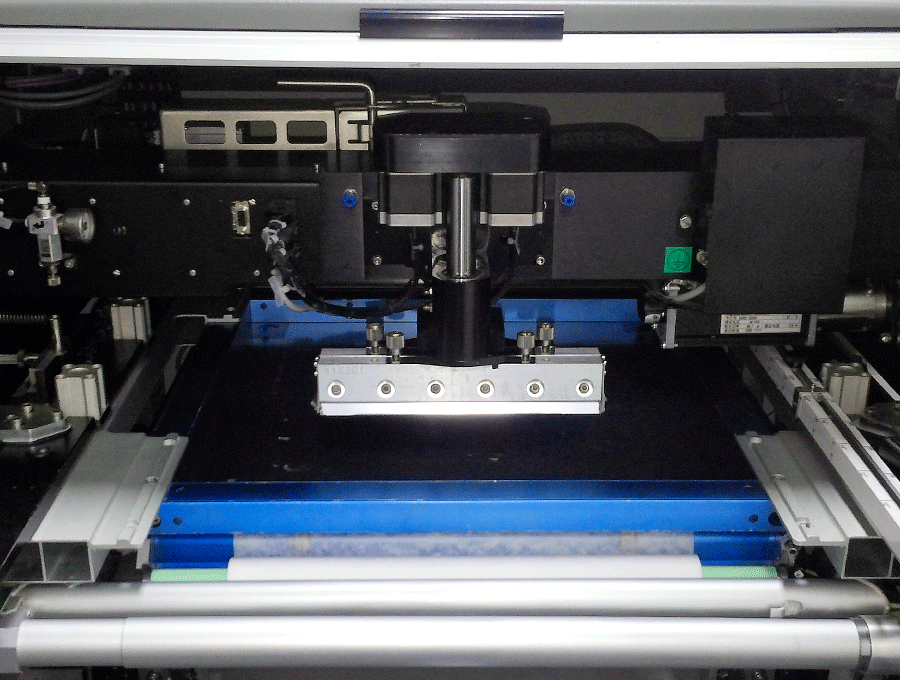

Stencil underside cleaning

In addition to the machinery cleaning of the entire stencil, the stencil underside or flipside cleaning right in the printer is an important factor for a reproducible error-free printing result.

Learn more about stencil underside cleaning and suitable detergents

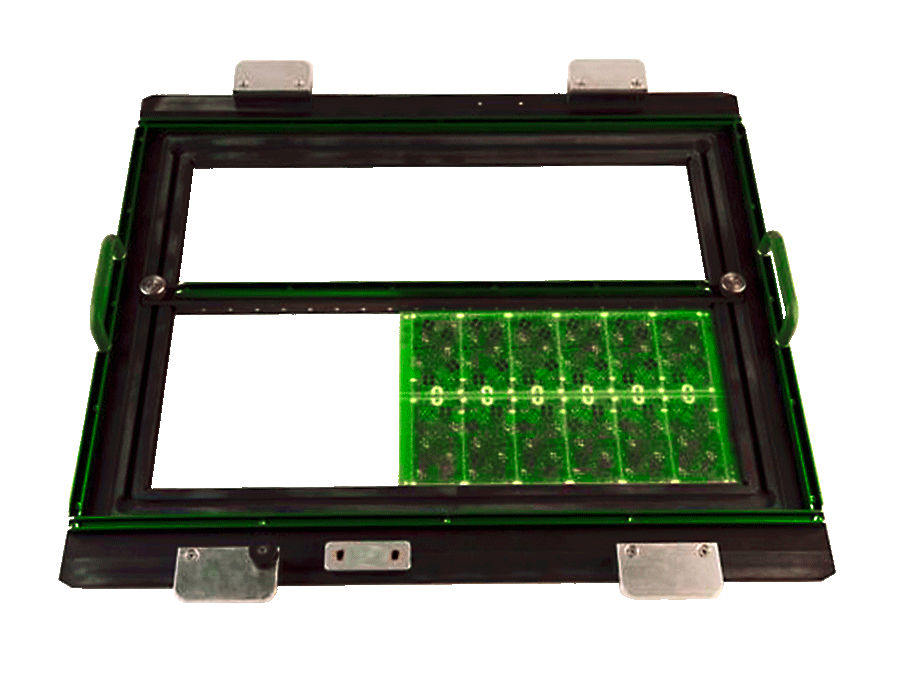

Solder frames, masks and carriers cleaning

Solder frames, masks and carriers need to be cleaned mainly from flux residues on a regular basis in order to reduce production rejects and to maintain the tools.

Learn more about solder frames cleaning, suitable systems and detergents

Soldering systems cleaning

Condensate residues, oils and greases in (wave) soldering systems and SMD reflow ovens, which can develop gradually, lead to reduction of diameters and thus to changes of air circulation parameters.

Learn more about soldering systems cleaning and suitable detergents

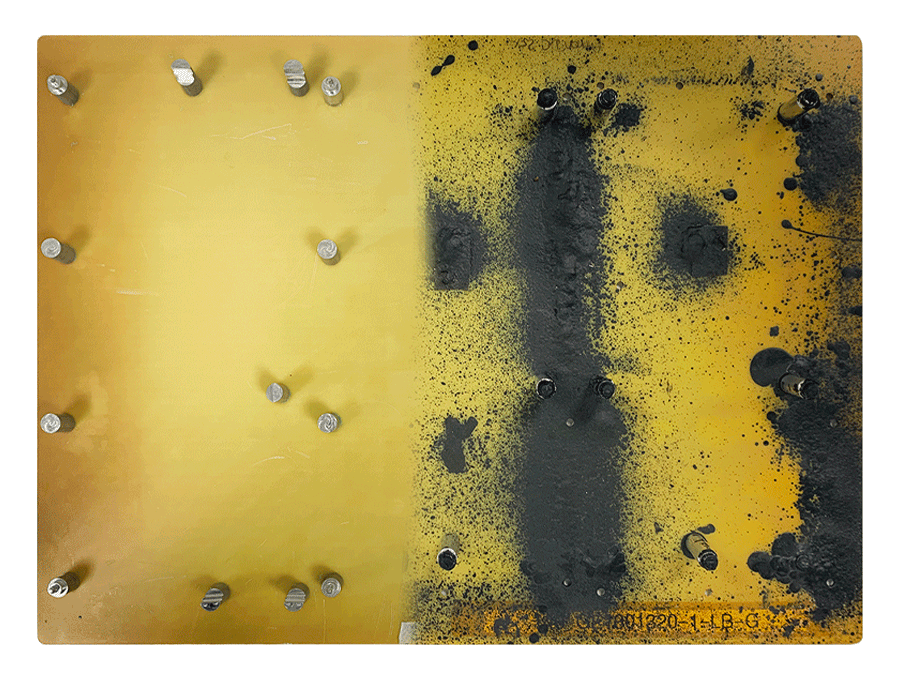

Paint stripping of conformal coating tools

Paint stripping from conformal coating carriers as well from coating systems is usually time-consuming and labour-intensive. Efficient cleaning helps saving time and money.

Learn more about paint stripping, suitable methods, systems and detergents

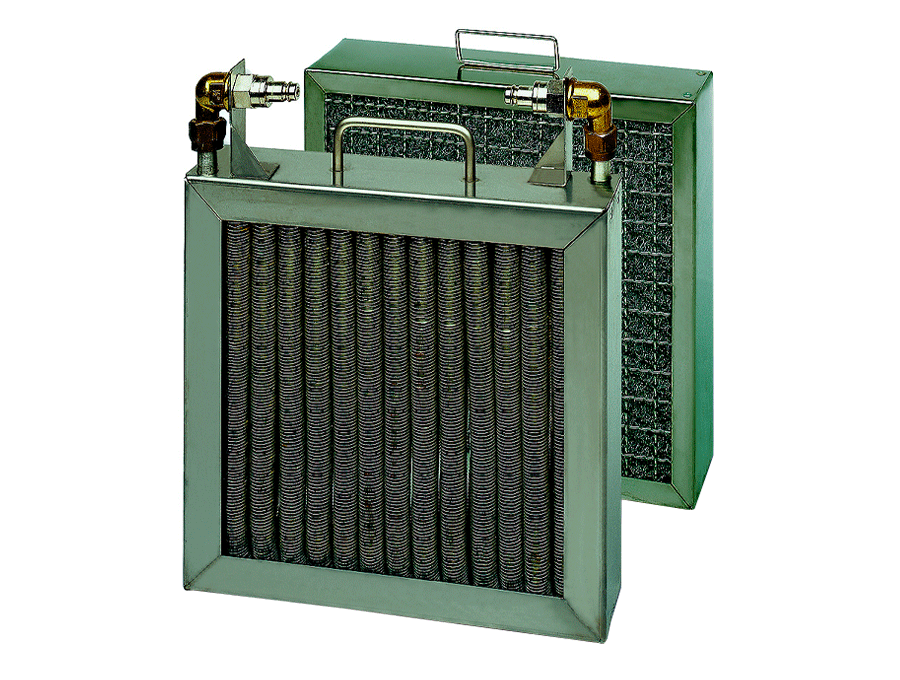

Condensation filter cleaning

Condensate traps, filters, coolers, cyclones, trays, reflow ovens, wave and selective solder systems - all these components must be cleaned regularly and thoroughly to maximize productivity.

Learn more about condensation filters cleaning, suitable systems and detergents

ESD areas cleaning

To avoid ESD damage to electronic assemblies or components with high internal resistance they have to be manufactured, handled, packaged and stored in an ESD protected environment.

Machinery parts cleaning

Components of production systems are often contaminated with condensate, flux, colophony, fat, grease oil etc., which easily disturbs the reliability of production processes.

Learn more about machinery parts cleaning, suitable systems and detergents

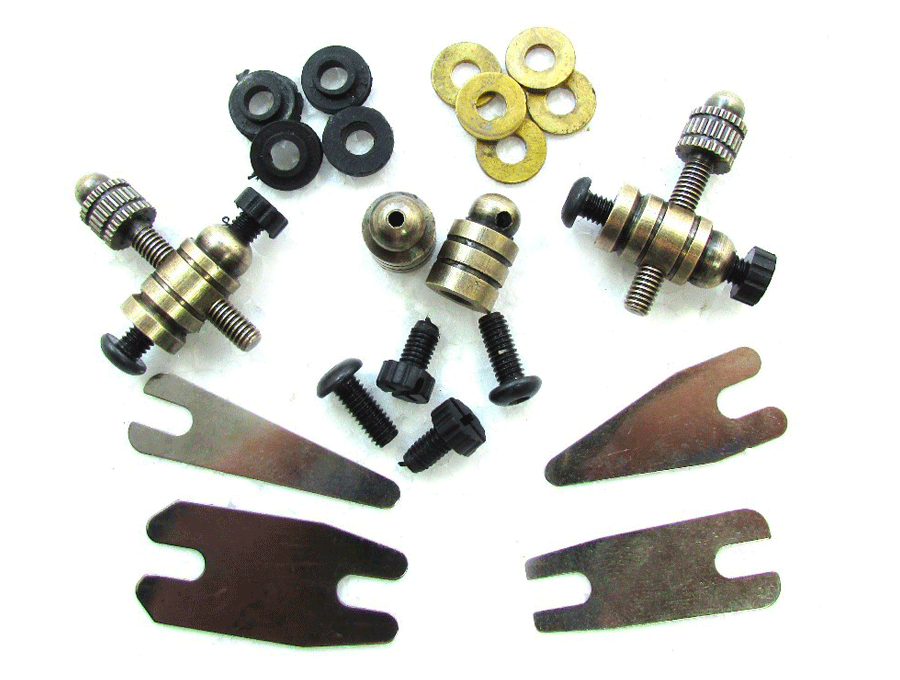

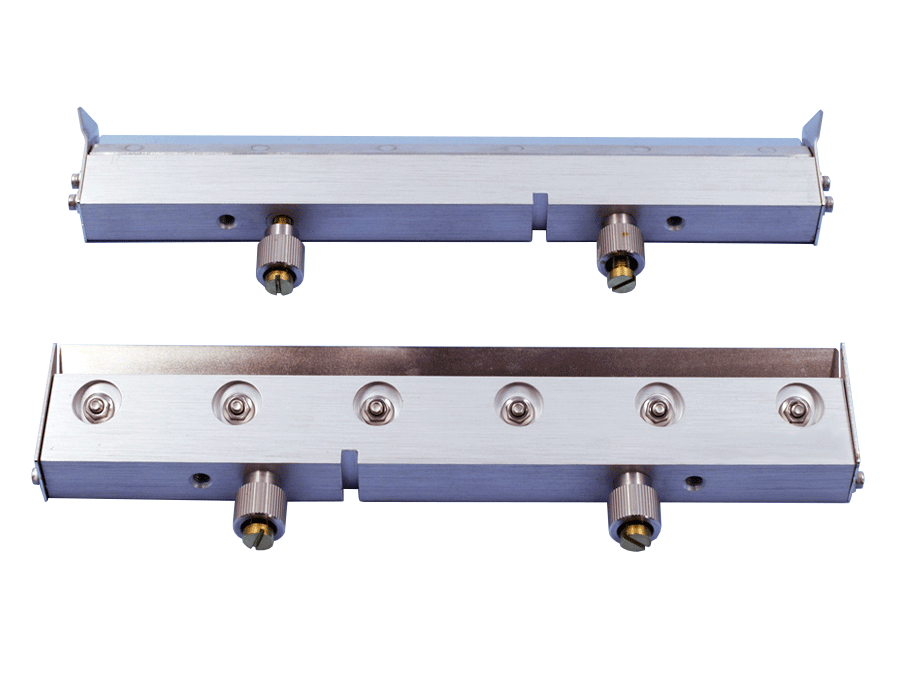

Manual cleaning of SMD tools

SMD tools such as squeegees and spatulas stained with residue from solder paste and adhesive need to be cleaned right after use in order to avoid hardening and to ensure trouble-free use again.

Learn more about manual SMD tools cleaning and suitable detergents