AQUBE® XV9 SuperTask

Cleans PCBAs, hybrids and misprints from flux residues, resin, copper, oxide and soldering support substances

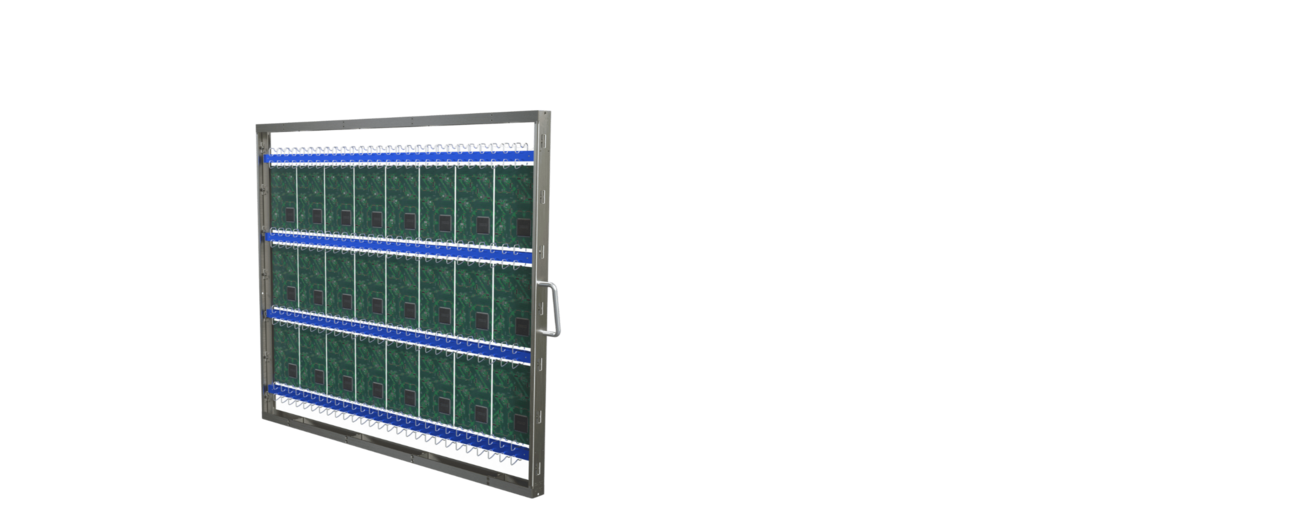

AQUBE® XV9 SuperTask is a fully automatic state-of-the-art ultra-fine cleaning system with a vertical rotor arrangement and a capacity of up to 96 eurocards per cleaning cycle. It is specially designed for cleaning hybrid electronics assemblies with very complex architectures and therefore extreme shading and unusually deep and hidden micro-spaces.

In the SuperTask special system, the vertically loaded cleaning good is sprayed frontally at high pressure. This means that even the most hidden areas and spaces are cleaned quickly and efficiently.

The parallel configuration of three tanks and three separate circuits as well as ClosedLoop water treatment ensures short cycle times and low operating costs, resulting in unprecedentedly low total cost of ownership.

Highlights

- Three-tank system with three separate circuits

- Average process time: 40 min/cycle = 25 s per eurocard

- Smart-Factory-ready: remote control, traceability (PLC data scanning and memorizing)

- Fully automatic 4-step (optional up to 5-step) process: cleaning, (MediumWipe®), rinsing (tap water), DI-/DM-water rinsing,

- VMH® TurboDigital hot air evaporative drying

- Horizontal PTFE mounted rotor system with eight ASYNCHRO® spray rotors for thorough wetting (no blind spots)

- Heater cleaning tank A, automatic water change for the rinsing circuit, DI-water system, DI-bypass processing, water measuring unit (ion contamination measurement), ion exchanger and fine filter systems as standard

- Processes and service intervals PLC controlled with event issuing and software control via touch screen

- Suitable for high temperature cleaning and rinsing up to 80 °C (176 °F)

- Fast and easy maintenance

Technical Data (Excerpt) | |

|---|---|

| Technology base | kolb PowerSpray® |

Standard capacity (per process cycle)

| 96 eurocards in four clamping frames of 24 cards |

| Process chamber dimensions | W 970 mm • D 955 mm • H 900 mm |

| Clamping space for PCBA, Misprints, etc. | H 840 mm x W 640 mm |

| Circuits | 3: Cleaning, Rinsing tap water, Rinsing DI-water |

| Volume Tank A (Cleaning) | 125 l |

| Volume Tank B (Rinsing) | 100 l |

| Volume Tank C (DI-/VE-Rinsing) | 125 l |

| Max. cleaning temperature | 80 °C (176 °F) |

| Filtration | 1. Full flow coarse filter < 2mm (0.08"), 2. 20“ fine filter (1 - 100 µm - process dependent) |

| Drying System | VMH®-TurboDigital hot air |

| Drying temperature range | approx. 45 - 120 °C (113 and 248 °F) |

| Footprint | 1700 mm x 1850 mm (66.93″ x 72.83″) |

Certifications

Downloads

back